Table of Contents

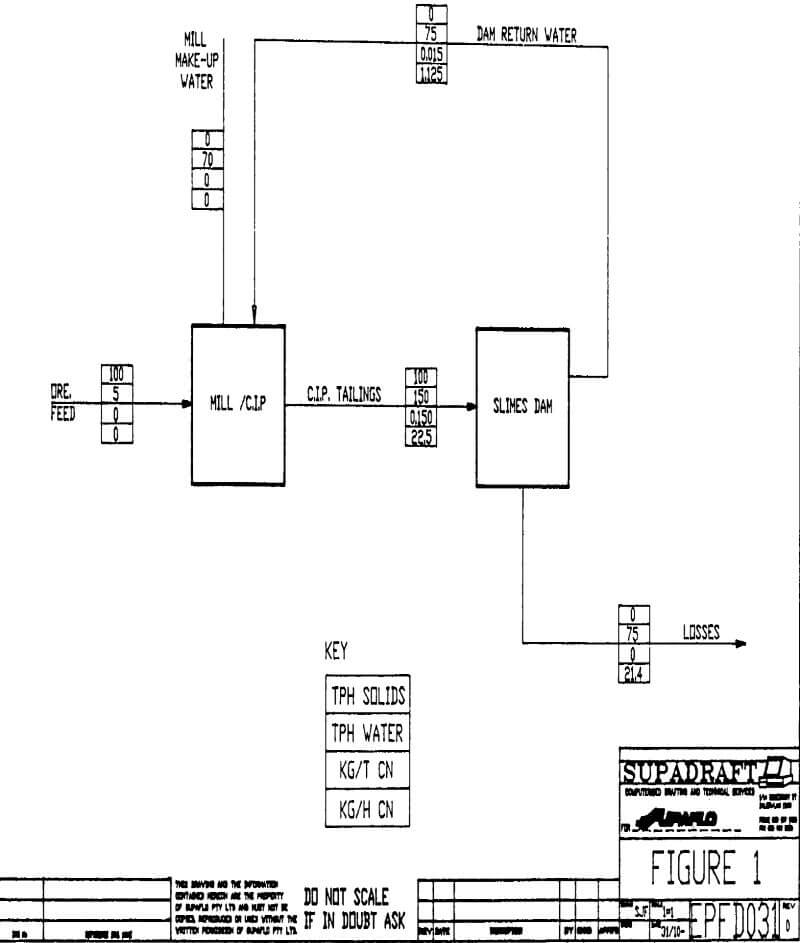

Degradation of cyanide occurs in the tailings water discharge to slimes dams. The degree of degradation or cyanide loss in the water recovered depends on a number of factors, but is usually assumed to be about 90%. The most important mechanisms of CN loss are through HCN losses and oxidation by oxygen in the air, which also assists in the hydrolysis of CN. These mechanisms are supported by the large dam surface area and the long retention time of the tailings water in the dam. By thickening the CIP tailings at the plant and recovering as much tailings water as possible immediately, these losses are avoided. The retention time in a High Rate Thickener (HRT) is less than 3 hours, and surface area is relatively small, and hence CN losses are negligible (which is not necessarily the case in conventionally sized thickeners).

Auto Dilution

A significant development by Supaflo has been the “Auto Dilution” facility. Since most CIP tailings pulps are at a density of about 40% solids, it is necessary to dilute them in order to achieve good flocculation in the thickener feedwell. In the above example, a capital cost of $54,000 and power cost of $32,000 p.a. was incurred by the installation of overflow recirculation pumps, piping and instruments. The “Auto Dilution” facility is an internal recirculation system, based on the principle that an hydraulic head differential exists inside and outside the feedwell because of the higher SG of the pulp inside the feedwell. Hence, by installing non-return ports into the feedwell wall at the appropriate level, supernatant water flows into the feedwell and dilutes the feed, without any need for external recirculation. A number of Supaflo tailings thickeners are now in service with this facility. Clearly, the economics improve significantly by incorporation of “Auto Dilution”. In the above example, the payback period would be reduced to 11 months.

In 1988, a CIP gold treatment facility was installed at the Cosmo Howley gold mine in the Northern Territory. The nominal design tonnage of the facility was 1.2 Mtpa, and it was decided to include a 15 m Supaflo tailings thickener, based on bench-scale testwork which indicated a throughput of 0.8 t/m²h to achieve an underflow density of 55% w/w solids. The Cosmo Howley ore was known to have a high carbonaceous component which would result in a “preg-robbing” environment if the residual cyanide were not maintained at a relatively high level, of about 800 ppm. The recovery of cyanide from the tailings was therefore a clear economic priority in this case.

Recovery of Water in Arid Areas

The recovery of process water from an in-situ thickener as compared to a dam reclamation system only is sometimes difficult to quantify, because evaporative and run-off losses tend to be site specific. However, it is generally assumed that, in arid areas, water recovery from tailings dams will not exceed 50%, and can be considerably lower. This problem is compounded by the fact that it is usually these areas in which bore water is difficult to find and costly to equip and reticulate.