The bacterial oxidation (BIOX) process for the pre-treatment of refractory ores for gold recovery was developed by the Genmin Process Research laboratory. Early work started in the late 1950’s when the bacteria strain, “Thiobacillus ferrooxidans” was isolated from effluents pumped from the West Rand Consolidated underground mine but at this stage the focus was on the recovery of uranium..

BIOX Plant Operation

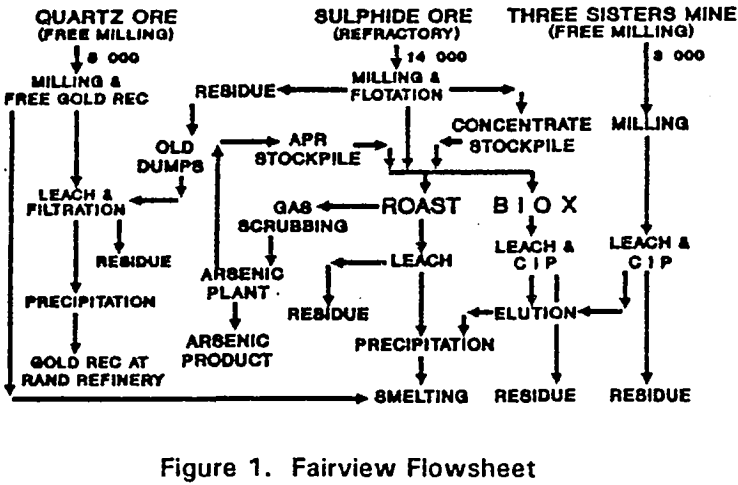

The Fairview Mine, situated near the town of Barberton in the Eastern Transvaal region of South Africa, has been in operation since 1912 and the present metallurgical plant was commissioned in 1955.

The bulk of the proven ore reserves are sulphidic and refractory. The main minerals are pyrite and arsenopyrite with trace amounts of chalcopyrite, sphalerite, stibnite, galena, pyrrhotite and pentlandite.

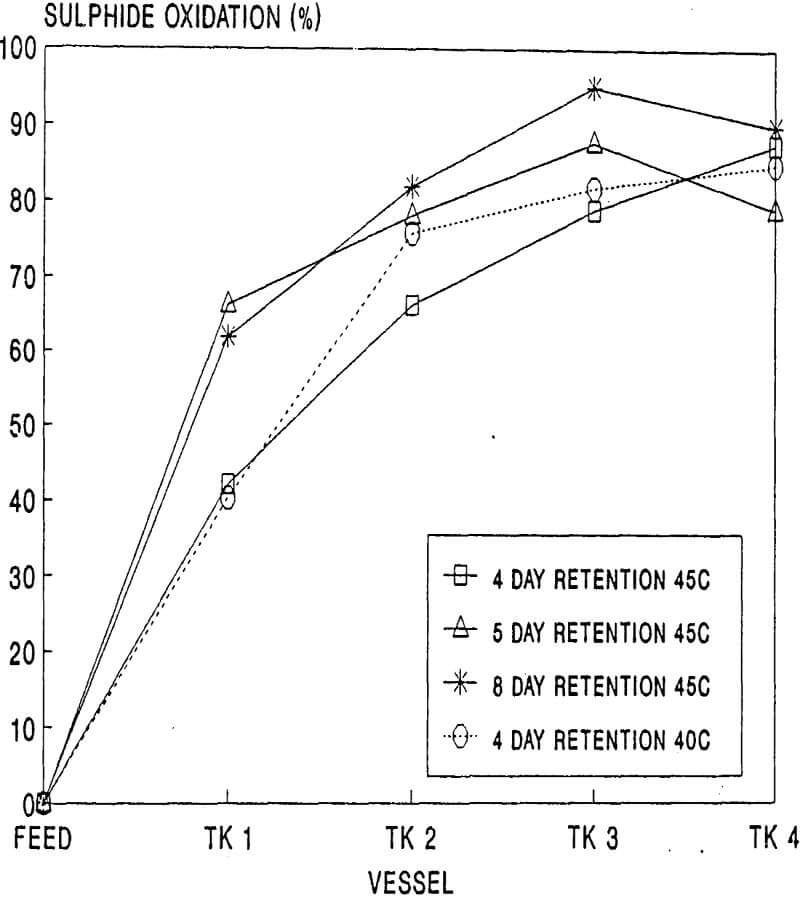

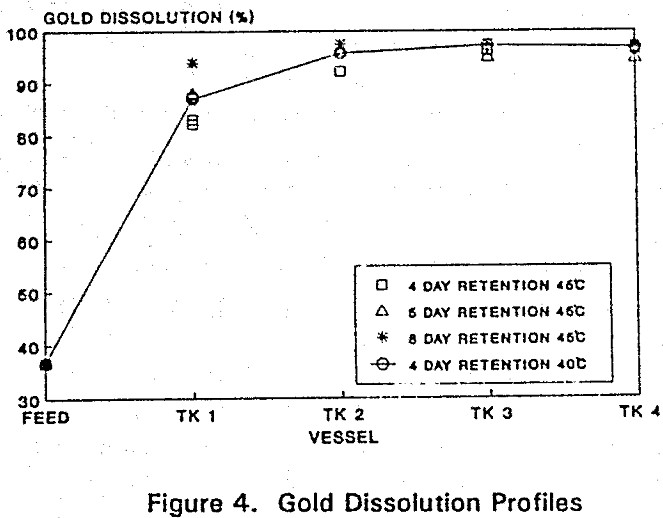

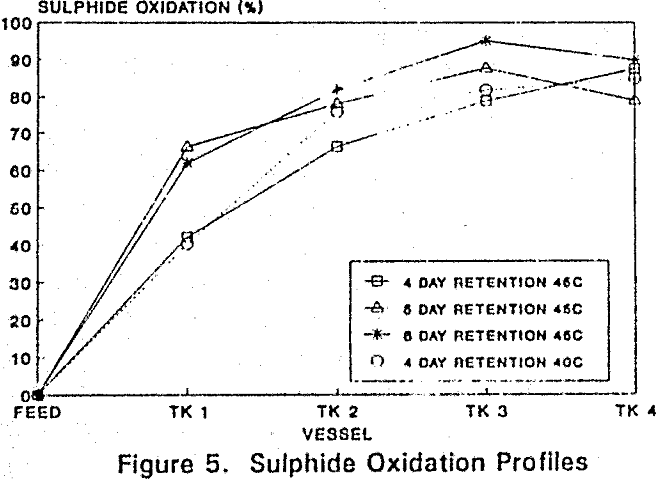

Temperature has been one of the most important control variables and as can be observed has been held at 40 °C by cooling. The temperature has often peaked at values as high as 53 °C for short periods. Although oxidation rates were still acceptable, a definite loss in bacteria activity was noticed. The time period at the high temperature was nevertheless too small to assess the effect on the oxidation rates.

BIOX Process Improvements

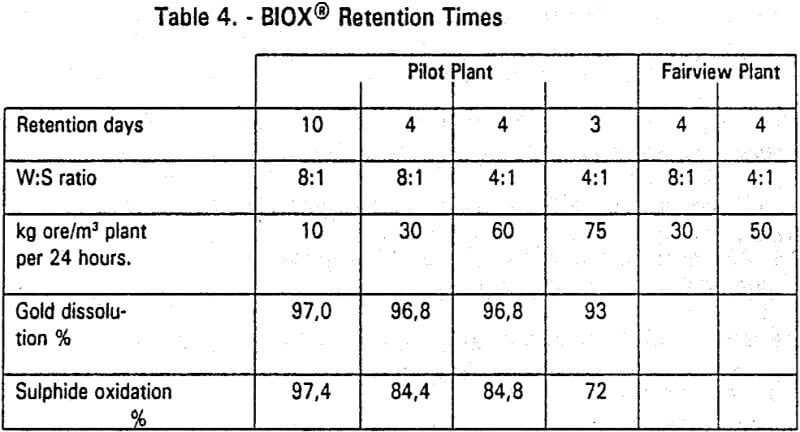

Three mini plants, each with a capacity of up to 100 kg per day are operated at Genmin Process Research. The plants are employed to confirm design parameters for treatment of concentrates for new projects internal and external and also to evaluate new process developments.

Possible new process routes are defined and evaluated on the pilot plant. Feasible developments are then implemented and confirmed on the Fairview plant.

Since 1984 pulp residence time and W:S ratio have been slowly decreased to improve the capacity of the plant.

High rates of sulphide oxidation in BIOX reactors result in high rates of oxygen consumption. Efficient air dispersion and oxygen mass transfer are thus required.

Results confirmed that these axial flow impellers consume less power, whilst maintaining good gas dispersion and oxygen mass transfer, and have the potential for significant operating and capital cost savings.

Similar Kla values are reported for the two types of agitators. Oxygen utilisation of the axial flow impeller at 17%, is however lower than the 27% achieved by a flat blade.

A second characteristic to a highly active BIOX plant is the high energy release.

All BIOX studies have, in the past, been conducted at a controlled maximum temperature of 40 °C.

At Fairview mine plant operating temperatures often exceed 40 °C during summer months, sometimes peaking at 53 °C.

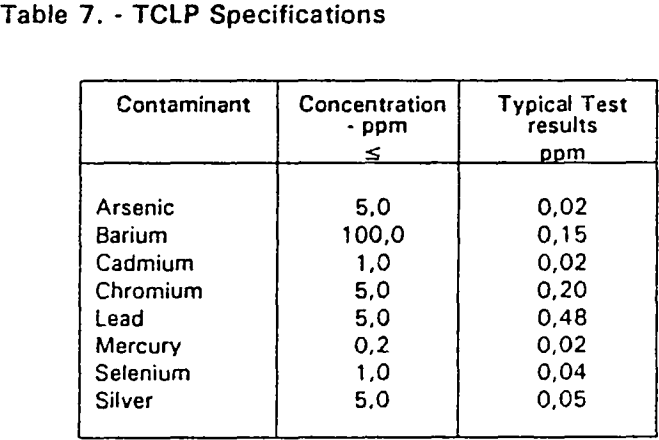

Stability of Precipitates

During the bio-oxidation process arsenic and sulphur are solubilised and the resultant effluents are neutralised by limestone and/or milk of lime.

The neutralisation is normally completed in two stages viz neutralisation to pH 5 in the first stage and then to above pH 8 in the final stage. This has the advantage of better control at a pH of 5 and hence formation of a more stable product. Use of limestone has an added economic advantage.