Table of Contents

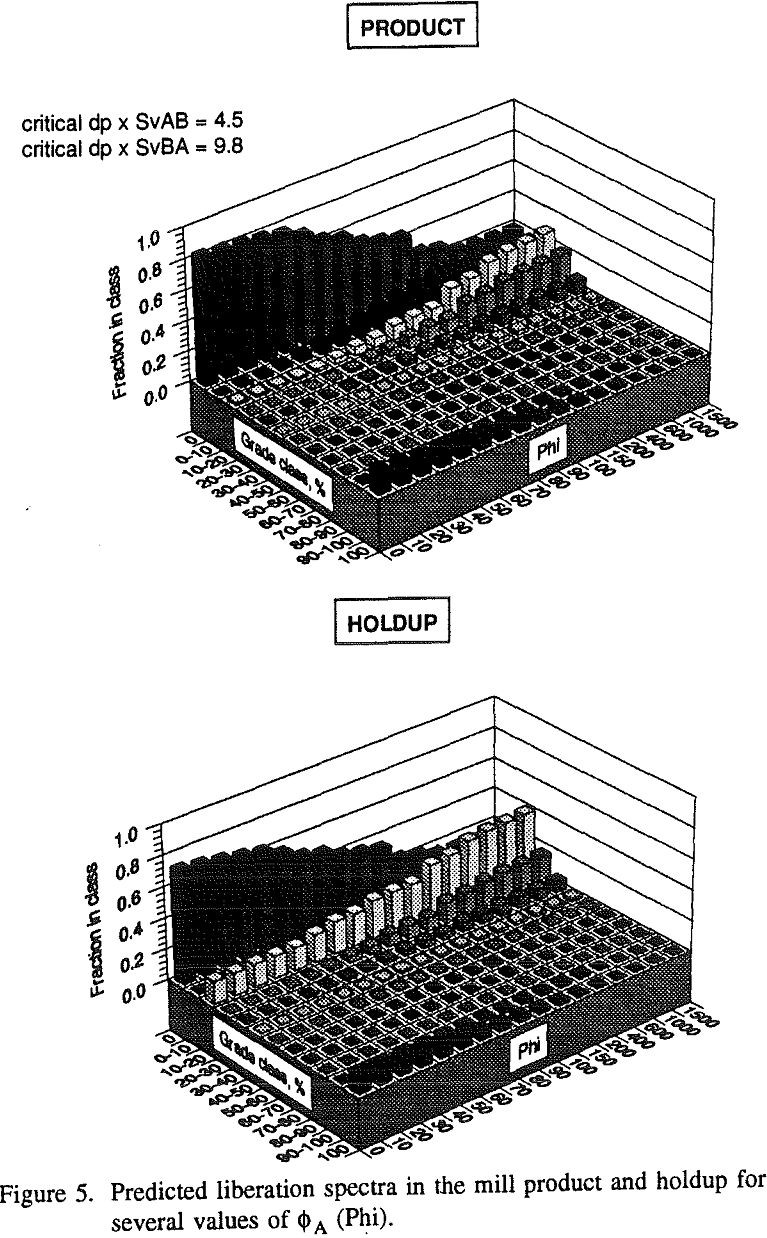

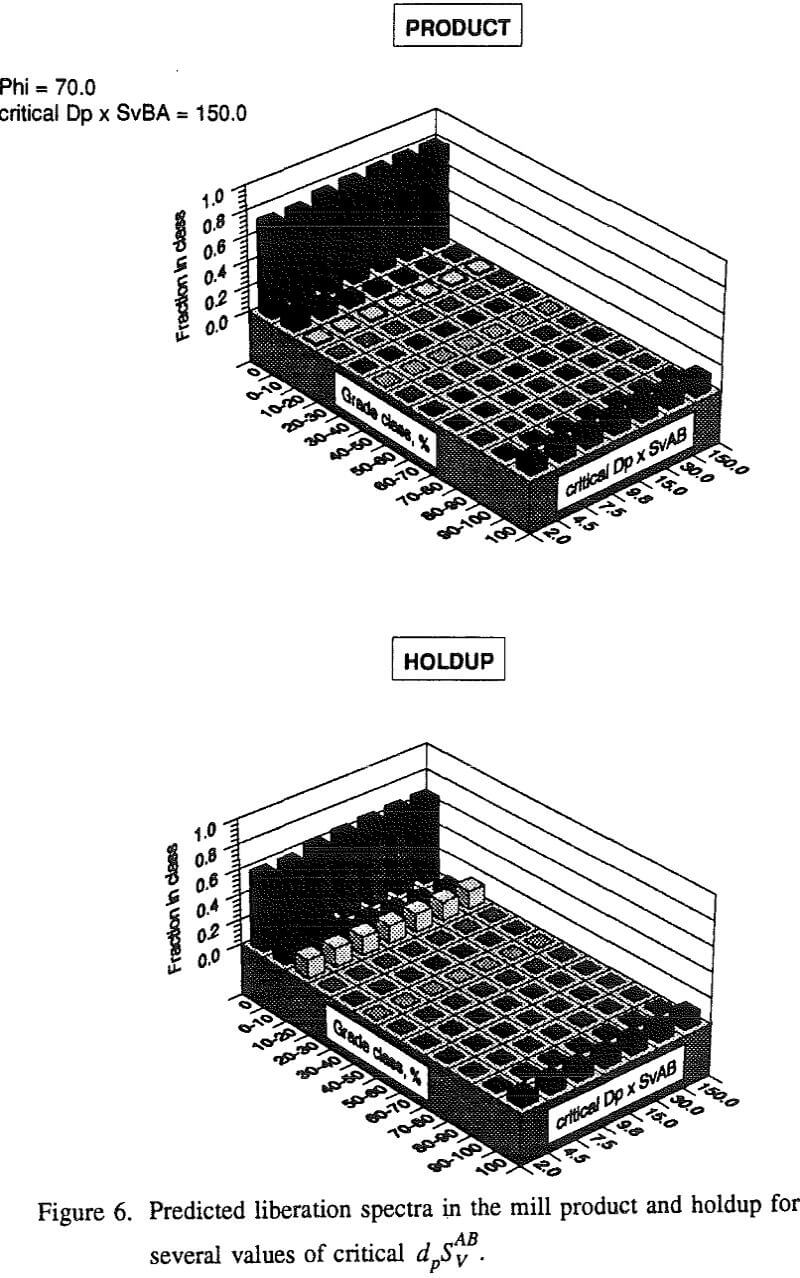

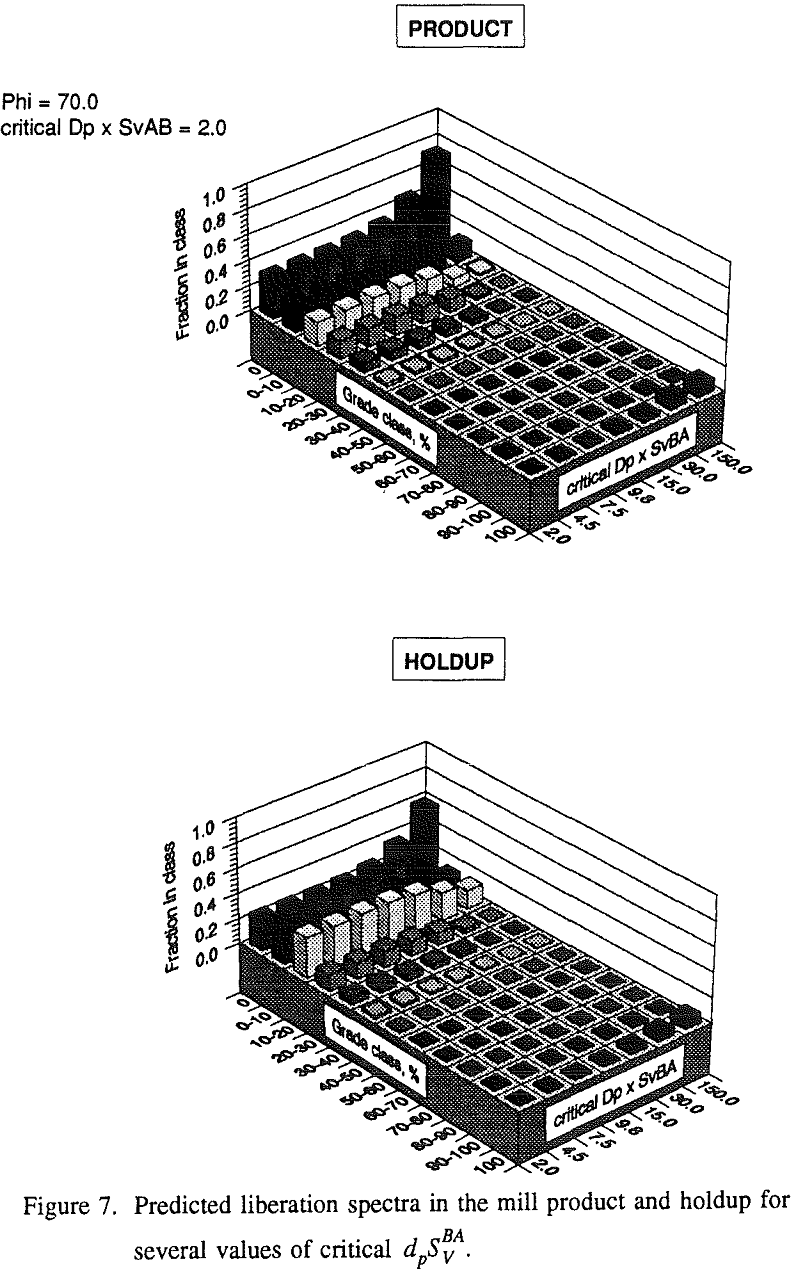

The calculation of the liberation spectrum in the product from a continuously operating ball mill is both important and difficult The liberation spectrum depends on the mineralogical texture of the ore from which the mill feed derives and also on the processing steps through which portions of the feed have passed prior to milling. These steps typically include classification by hydrocyclone or separation operations, such as flotation and gravity if the mill is regrinding tails or concentrate. The calculation procedure that is based on the population balance procedure is understood in principle, but the indiscriminate use of this method requires hundreds of parameters that must be estimated—a hopeless task under most conditions.

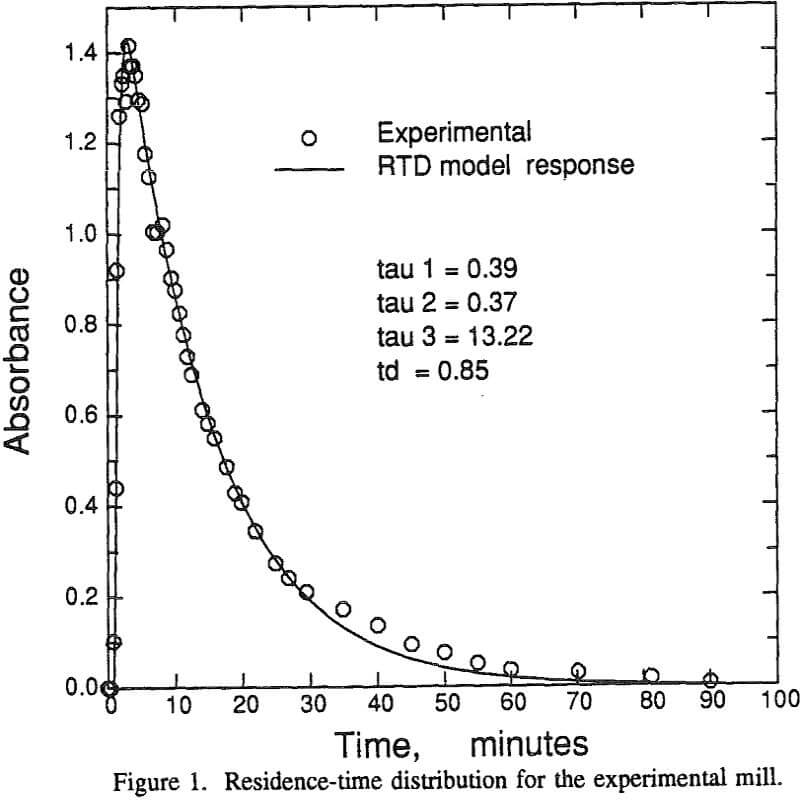

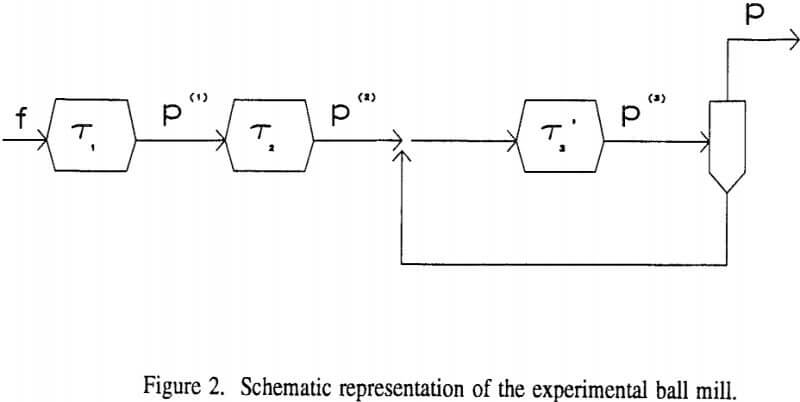

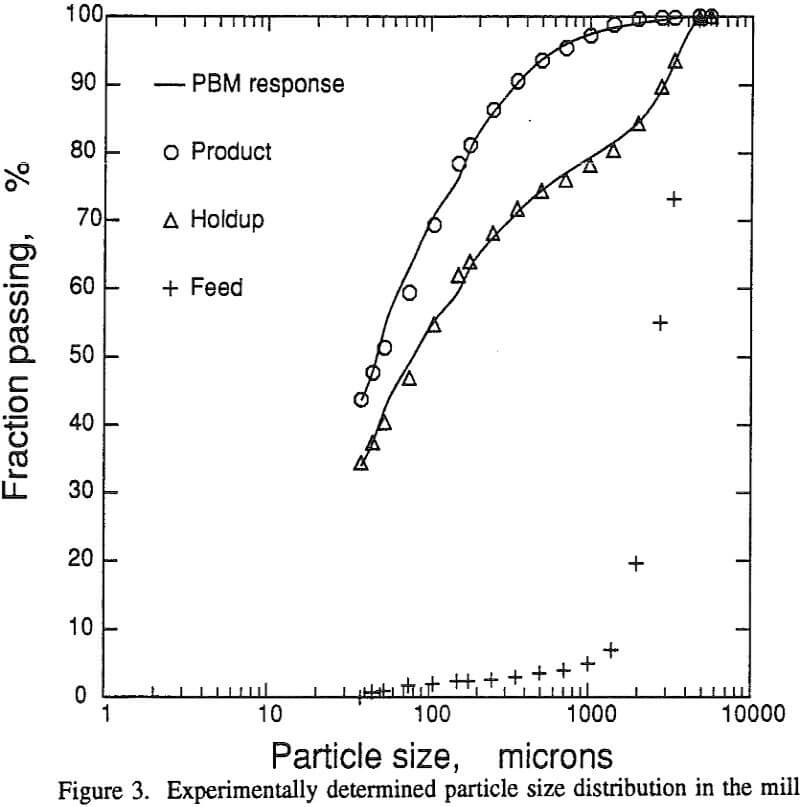

The initial experimental work was aimed at characterizing the flow pattern and mass transport characteristics of the experimental mill. The residence-time distribution was established by an impulse test using a liquid-phase tracer. The measured response of the tracer indicated that the mill behaved as three mixed regions in series. The particle size distributions in the mill holdup and the mill product at steady state allowed the estimation of the selection, breakage and overflow classification processes that describe the comminution process.

Experimental

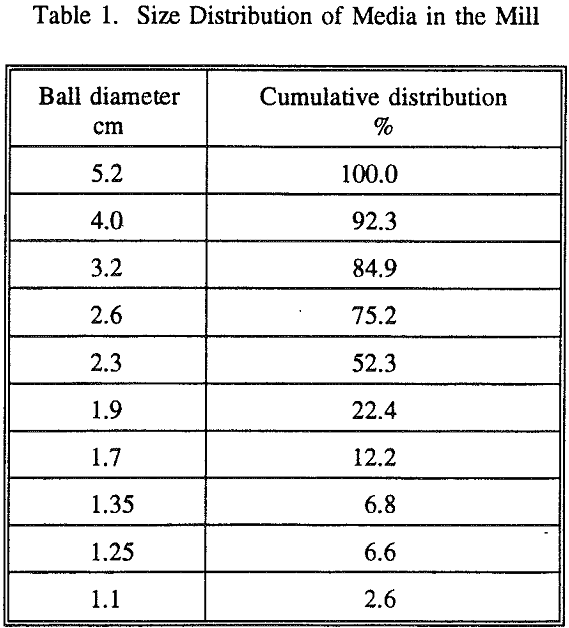

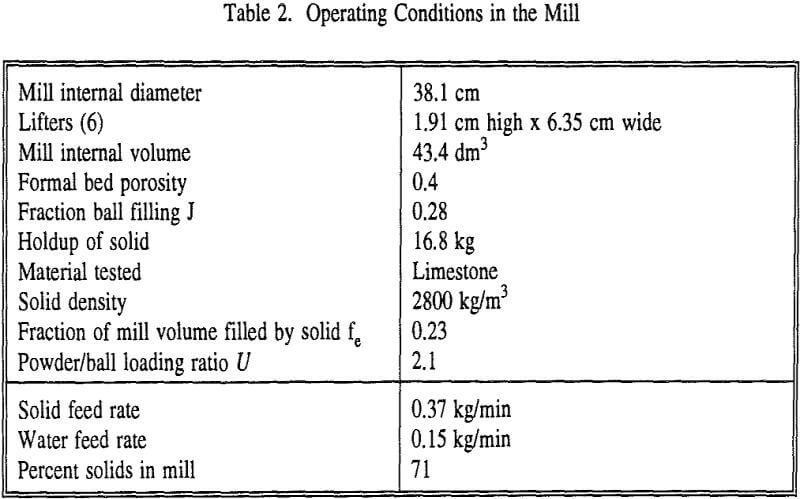

A Denver 16″ x 16″ overflow ball mill was used. The feed was fed dry through a vibrating feeder. Water was supplied to the mill by a peristaltic pump which maintained a constant flow. The mill was charged with a mix of steel grinding balls having a size distribution given in Table 1.

Residence-Time Distribution Function

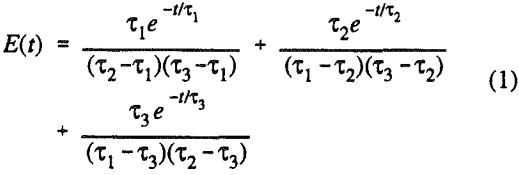

The measured concentration response was found to fit the response to three perfectly mixed regions in series with a slight time delay resulting from the distance-velocity lag in the feed pipe from the injection point to the mill entrance.

The Comminution Model

The mill was assumed to behave as three mixed regions in series with post classification in the last stage returning oversize material to that stage.

The size distribution of the product and the mill holdup were simultaneously fitted and the following parameters minimized the sum of squared deviations from both measured distributions simultaneously.