The most serious problem for on-line coarse particle size measurement from a conveyor belt by image analysis is the overlap phenomenon that occurs between adjacent particles. In order to achieve image separation, three methods have been considered for the analysis of projected particle images obtained from overlapped onyx stone and copper ore particle beds of particle size which ranged from 12.7 to 19.0 mm. It was found that the 2-D maximum entropy method and the three-module strategy edge detection procedure are not well suited for the separation of particle images with a rough surface condition.

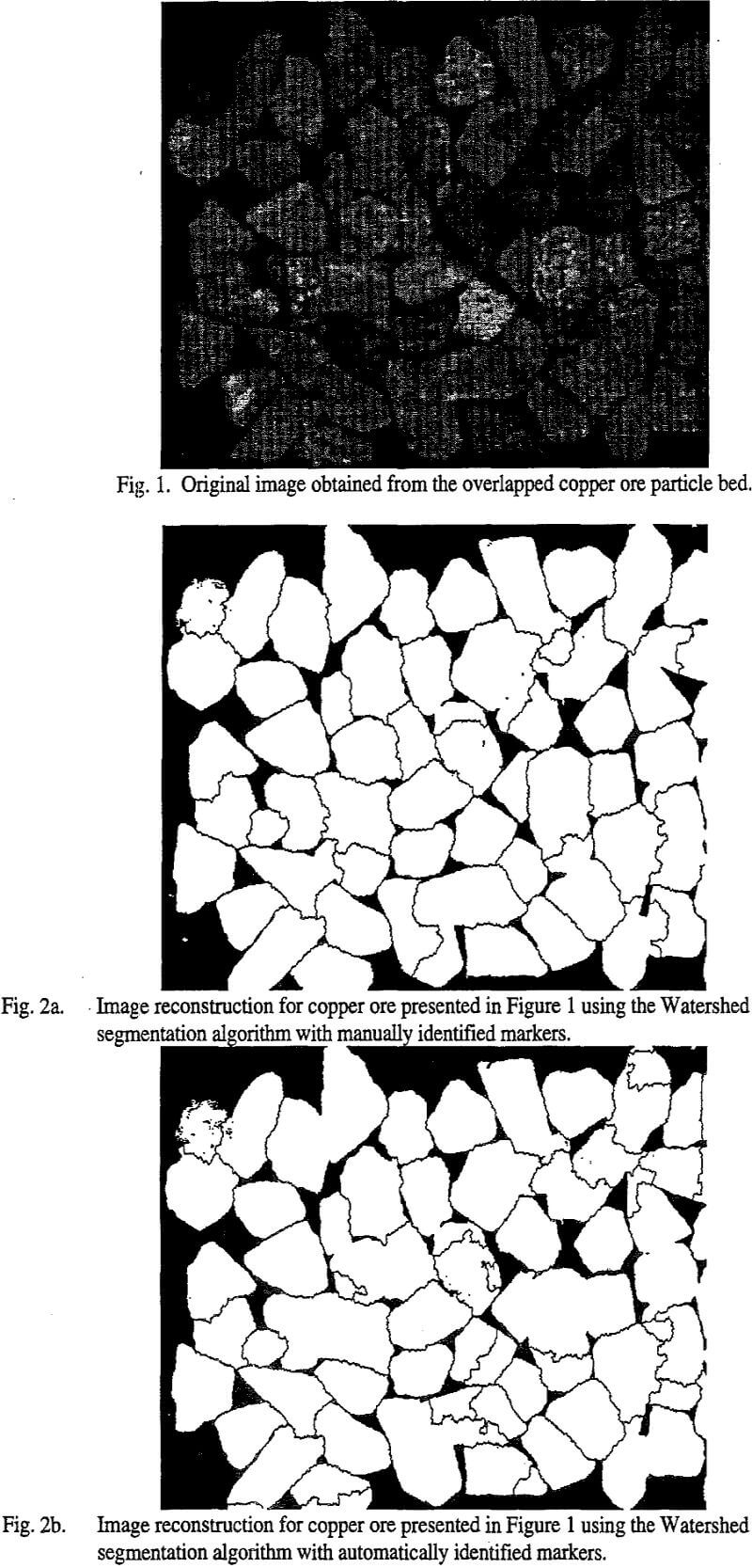

The basic idea about this Watershed segmentation procedure is that it still relies on the natural surface condition of the particles but not as much as in other algorithms. It assumes that a two dimensional particle image can be seen as a topological map with mountain peaks, ridges and valleys. Now imagine what will happen if there is a hole at the bottom of each valley from which water is released to fill the valley.

The key point in making this Watershed algorithm functional is to accurately identify those inside markers, namely those holes at the bottom of each valley. For the purpose of on-line processing the inside markers have to be determined by a fixed processing procedure instead of being determined manually by trial and error. In this regard, an “Edge Preserving Smoothing” technique is applied to the overlapped particle image first. The purpose of smoothing is to eliminate the fluctuation of highs and lows on the particle surface as much as possible but preserve the edge points.

Once the overlapped particle image is separated the measured linear intercept distribution then has to be transformed into the corresponding volumetric size distribution. In discretized form, the transform equation used for the non-overlap case is described as follows:

To ensure the simulation work is valid, the kernel function for the non-overlapped PARGEN particle images is compared with those from experimental measurements and the results are shown. It is obvious that the PARGEN generates particles closely matching the morphological characteristics of those particles being studied, i.e. the crusher products for copper ore, coal and onyx stone.

The measured kernels for partial particles are shown according to exposed area. It should be noted that the kernel function for the partial particles was measured from projections of overlapped particles of the same size. Also it is evident that for partial particle projections with more than 90% exposure, the kernel function is equivalent to that for non-overlapped particle images.

Further simulations have been done to determine the effect of particle size on the overlap problem and preliminary measurements have been made for a complete size distribution. It is evident that particles with smaller size have a higher chance to be hidden inside the particle bed. A coarser particle size distribution was observed for the exposed layer. This phenomenon will be taken into consideration and quantified in future research.

Most importantly, the method selected must be workable for plant situations, i.e. must automatically accommodate the fluctuation of data collection (image capture) from a moving belt. Therefore the image/data analysis method cannot be too restrictive. The last step in solving the overlap problem is to transform the linear intercept distribution to the corresponding volumetric distribution, the traditional size distribution.