Table of Contents

- The Characterization of Comminution Efficiency

- Particle Breakage Considerations

- Efficiency Comparisons for Crushers and Mills

- Mechanical Inefficiencies

- Examples of Comminution Circuit Performance

- Compaction Type Crushing in Roll Crushers

- Operating Improvements To Conventional Crushing And Grinding Circuits — The Cyprus Sierrita Operation

- Plant Design using high Energy Crusher Technologies

- Using Efficiency Factors in Comminution Flow Sheets

Recent research into the mechanisms of crushing processes has led to the establishment of new criteria for the effective design and operation of comminution plants. This paper reviews this work and gives examples of the productivity gains and cost benefits that have been achieved in the practical application of these findings.

Large cost reductions have been reported in energy and metal consumption per ton of finished product by employing efficient crushing processes in the breakage of coarser particles, and in this paper, the authors review research findings that have led to improved performance in crushing and grinding as well as the methods used for the practical adaptation of this technology into existing comminution machines.

In recent years, proposals have been made that other devices such as autogenous or semi-autogenous grinding mills can be used to break coarser particles efficiently and that specialized crushing devices such as rolls can make fine products. The argument developed in this discussion, however, is that such equipment, whilst being an expedient means of solving a practical problem of processing materials that are difficult to crush and/or screen in a conventional manner, does not always offer the most efficient production in terms of comminution energy application.

The biggest mechanical differences between the crushing and mill processes can therefore be summarized as follows:

- Crushers draw power and apply energy as a direct result of their engagement of feed particles. Crushing power is dependent upon a long list of physical properties that include material characteristics such as hardness, operating conditions such as feed rate and mechanical characteristics such as crushing chamber shape and motion. Grinding mills draw power as a result of lifting a weight of media, and this tends to be a constant independent of feed rate or other physical properties of the material to be comminuted.

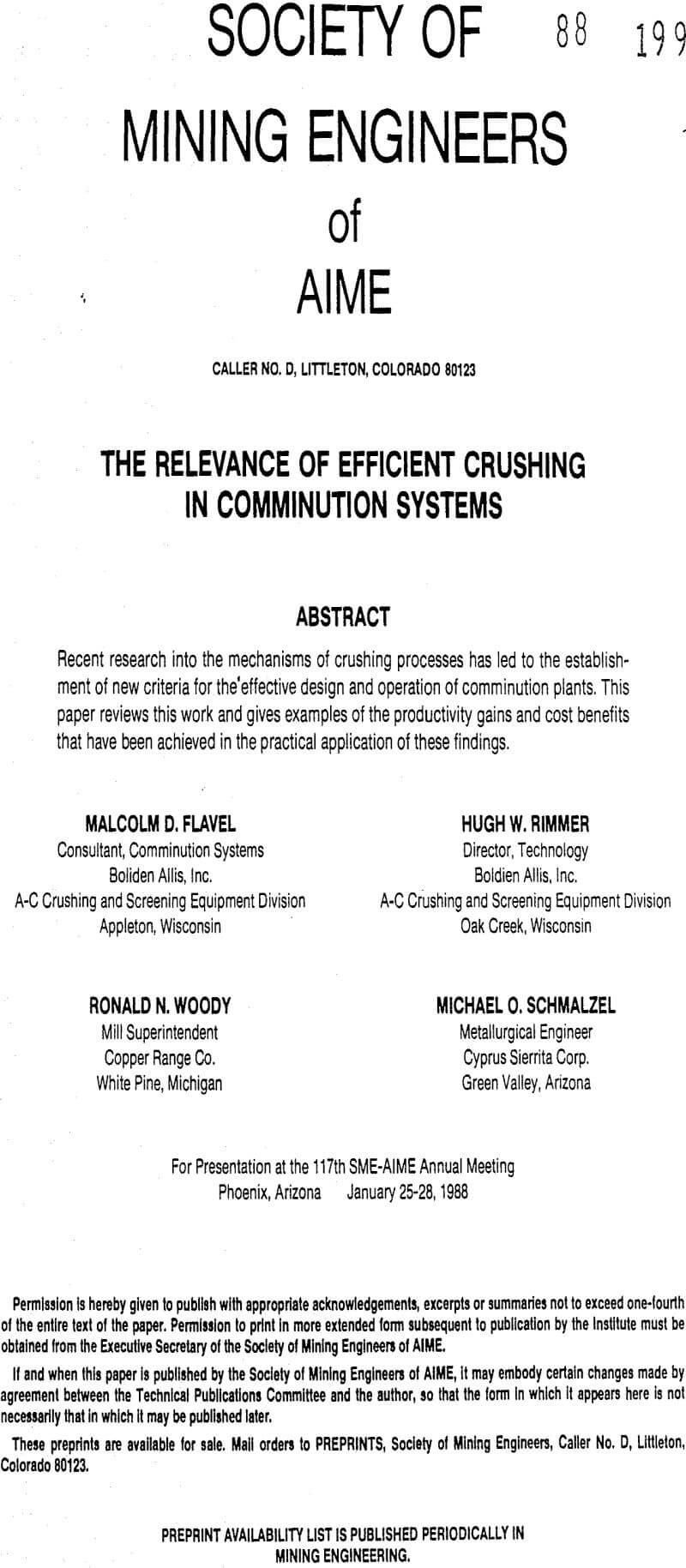

- Crushers preferentially break coarser material due to their crashing chamber geometry, whereas mills break less coarser particle sizes above a certain size because of limited energy that is contained in the individual pieces of media.

- Crusher fragmentation comes from a limited event process, whereas grinding comes from a multiple event process.

The Characterization of Comminution Efficiency

The Third Theory of Comminution proposed by Bond in 1953 stated that the work input is proportional to the new crack tip length produced and equals the work represented by the product minus the work represented by the feed.

W = 10 WI (1/√P80 – 1/√F80)…………………………………………………………………….(1)

Where:

W = Work in kilowatt hours

WI = Quantity of energy (in kWh/st) necessary to reduce one short ton of a given material from infinite feed size to 80% passing 100 µm (microns)

P80 = Size which 80% of the product passes in µm (microns)

F80 = Size which 80% of the feed passes in µm (microns)

The Bond Theory assumes that average physical properties exist in all materials and some researchers have suggested modifying exponents in Bond’s equation to obtain better correlation for a particular material. However, Bond fixed the exponent for feed and product size in his equation at 0.5, based on a considerable data base of commercial and research material for both crushing and grinding, in order to facilitate the use of relatively simple empirical efficiency factors needed to estimate grinding mill performance.

Particle Breakage Considerations

Although the Bond Work Index approach provides us with a general measure of performance, it does little to elucidate the underlying reasons for the differences in efficiency and we now review certain aspects of breakage research that explain the detail of the breakage events taking place in these systems. It is not our intention here to review the theory in any detail but rather to highlight certain empirical observations made in the course of various investigations into single particle/single event and multiparticle/single event breakage.

One important finding from these studies was the identification from the high speed movie photographs of the kinetic energy that was contained in large fragments flying at high speed after initial breakage. This was also shown to cause significant secondary fracture of such particles in the appropriate environment.

The reduction ratio was more than 3:1 with secondary breakage in the air environment compared to only 1.1:1 when the particle was surrounded by gelatin. For these tests, the level of reappearing kinetic energy at approximately 45% of that originally applied to cause initial fracture. The kinetic energy was contained in broken particles that were timed at a speed of approximately 15 meters per second travelling away from the center of the original specimen.

The high energy pendulum impact tester is used to establish work index and size distribution (breakage function) properties for various materials. Details of the procedures have been published. This device breaks material in a free environment with excess energy (that not being consumed by breakage) going into the rebound pendulum.

The twin pendulum high energy tester has been used to break specimens of similar type materials at various energy levels.

The energy differential at 80% passing size is less than the differential for 80% passing at higher energy levels. The attention of the reader is also drawn to the fact that all the above breakage events took place with the strain energy input into the specimen of between 10 and 30 milliseconds. The bulk of the fractured particles (75% to 95% by weight) are finer than 12.7 mm (½ inch) and these are so small that they are unlikely to be selected and broken again between the crushing chamber’s metal surfaces. Because of this phenomenon, the strain input energy level occurring during this short time span determines the resulting product size distribution for the crashing process. In other words, it is the crushing energy intensity (power rate) which determines the fine particle distribution, and it is unlikely that this size can be changed by a second or (even less likely) a third blow in a single pass through the crashing chamber.

Efficiency Comparisons for Crushers and Mills

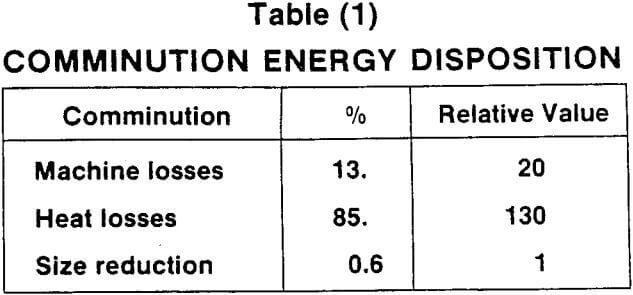

The optimal application of these observations to the design and operation of comminution devices is not always obvious. For example, the National Research Council’s report postulates, in the section describing machine efficiency measurements, that the increased surface energy for particles broken in all types of machines typically accounts for less than 1% of that applied to the machine’s driving mechanisms. From this observation it is concluded that such comminution processes are grossly inefficient.

The report’s recommendations suggest that the machine and heat losses are related to machine design and that the potential for energy saving is far greater from research into mechanical design and machine dynamics than it is from the research into the physics of fracture itself.

Based upon the Boliden Allis (previously Allis-Chalmers) high energy pendulum breakage study work as well as the single particle research of Bergstrom, it can be shown that this type of recommendation can be wrongly interpreted and extremely misleading in its view of potentially available energy savings for the following reasons.

- The predominant mechanism of breakage in most commercial machines is compression induced tensile and shear failure of the particles undergoing comminution.

- The majority of the heat losses are associated with and are an inherent part of the fracture physics of this form of processing.

- Crushing and grinding devices of the type currently employed can be shown as being relatively efficient machines, particularly if they are operated in a proficient manner, i.e., supplied with optimum feed size and processing environment.

Process Inefficiencies

These normally include material and process related characteristics such as excessive crushing surface movement through the particle after initial engagement and inadequate void space between particles. These situations often generate compaction, which leads to wastage of applied strain energy, attrition breakage and/or friction generated between sliding particles.

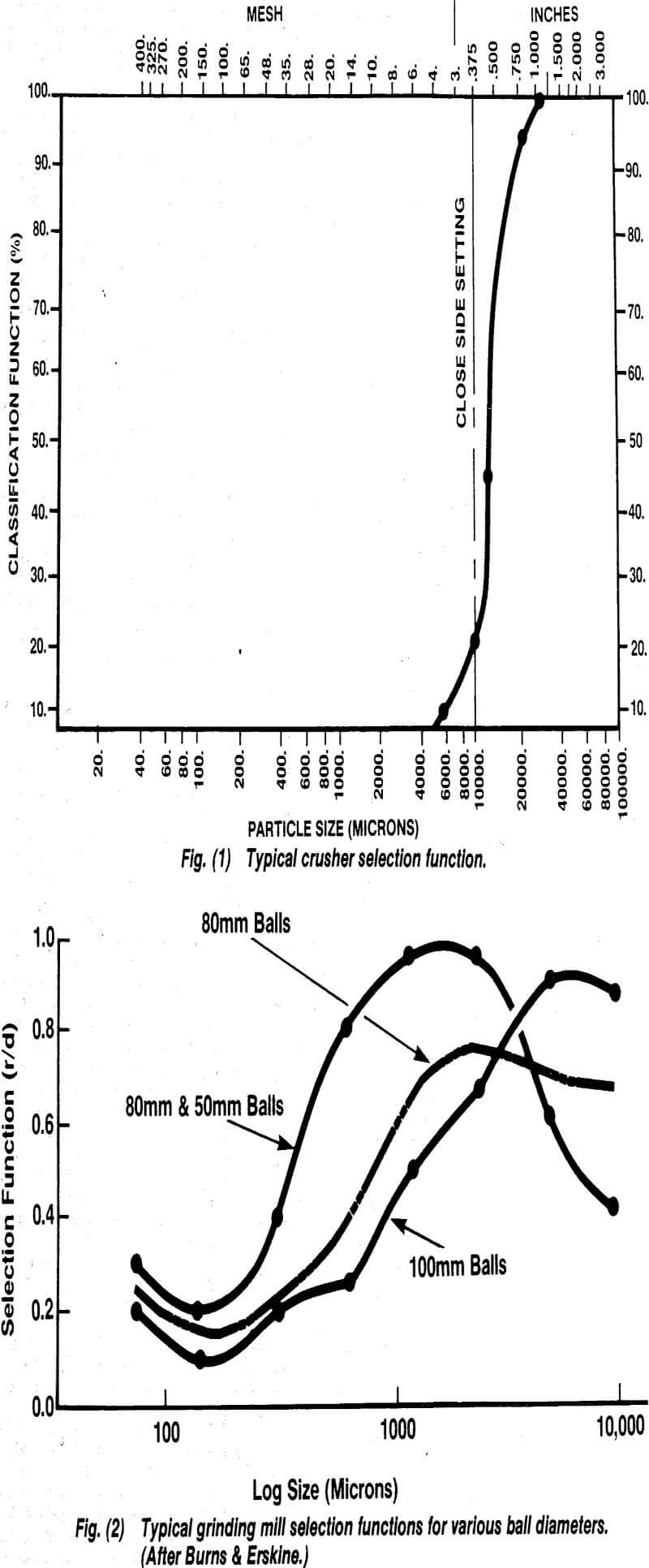

Conversely, in grinding mills the balls, rods, rocks or pebbles are lifted to some height which is necessarily a function of the mill’s diameter and the energy gain within individual pieces of media is directly related to the mass of that piece.

Bond’s studies of media action within grinding mill compartments such as that published in 1960 for rod mills showed that under adverse conditions such as those in a grinding charge containing broken rods, the mill efficiency suffered catastrophic reduction. For the particular case discussed in this article, the 10-foot diameter by 16-foot long rod mills had an operating work index of 33.3 kWh/t, which was approximately twice the laboratory value. During the discussion, Bond hypothesized on where the wasted energy was going and calculated an average lift for the average rod to consume the registered mill power.

In ball mills and semi-autogenous mills, the largest size steel balls in general use are 125 mm (5 inches) diameter, and balls down to 25 mm (1 inch) are typically available in the charge. If we consider that this size range of balls is in a 9.14 meter (30 foot) diameter mill and the average lift is 3.05 meters (10 feet), the available maximum energy when impacting 76 mm (3″), 51 mm (2″), 25 mm (1″) and 13 mm (½”) diameter rocks of S.G. 2.6.

Mechanical Inefficiencies

These include factors such as mechanical losses caused by friction between components within the crushing device mechanism, strain energy absorbed by stressing the crusher’s frame and plastic deflection on the crushing surface contact points that is not returned (by elasticity) to the breakage event.

The energy intensity within the crushing chamber will differ for various machines. The wide range of eccentric throws and connected powers for various units will give different crushing impacts, which might be considered analogous to the laboratory test pendulum. The angle of the mantle for the crushing head varies between manufacturers as does the length of the crushing zone from less than 200 mm (8 inches) to more than 600 mm (24 inches), but, as has been indicated from the pendulum size distribution correlations, it is the energy input to the feed material which determines the reduction and size distribution. Eccentric throw and chamber shape appear to have a little influence.

Since the original publication of this information, some cone crusher machine users have brought to our attention criticism from other crusher manufacturers concerning the theoretical accuracy of this published material. The correctness of the postulation can be verified by studying the relationships between crusher forces and how the energy is applied to the processed material.

The main cause of failure of crusher bodies, as experienced at MIM, is fatigue and to some extent, wear. Because of the high inertial loads in such crushers, occasional peak stresses may exceed design limits and therefore the fatigue life will never be infinite. Indeed, much of the fatigue damage results from a relatively few of the total load cycles if these will exceed the general stress level. Most fatigue failures are usually the result of variable tensile or torsional stresses. However, compressive overload can result in localized yielding so that on removal of the applied load the yielding area is left in a state of residual tensile stress.

Examples of Comminution Circuit Performance

The unit production operating costs for larger SAG plants have been shown to be less than the older conventional ones by Bassarear and Hinken, both in 1982.

Some discussion is warranted because such scale up can show cost productivity gains even though the larger scale operations themselves might be less efficient in terms of energy and metal consumption.

The Henderson mine and concentrator in Colorado was built to expand the existing operations of Climax Molybdenum Company during the late 1970’s. The older Climax mine and concentrator used conventional crushing and single stage ball milling flow sheet that had the following comminution equipment installed:

3 – Primary gyratory crushers

2 – 1.22M x 1.52M (48 x 60) jaw crushers

14 – 2.13M (7 ft.) cone crushers

8 – 2.74M x 2.44M (9′ x 8′) ball mills

4 – 2.74M x 2.74M (9′ x 9′) ball mills

8 – 3.96M x 3.66M (13′ x 12′) ball mills

The newer Henderson concentrator uses only one primary crusher and a unique single stage semi-autogenous grinding system comprising three 8.5M diameter x 4.26M (28 ft. x 14 ft.) mills and one 9.14M diameter x 3.35M (30 ft. x 11 ft.) mill. By that time Henderson unit production costs relative to the older Climax operation had been reduced from 115.1% in 1979 to only 89.8% in March, 1982. It should be noted, however, that the 16.5 kWh/t of grinding energy for Henderson is much greater than Climax’s, on an ore of similar hardness. This 16.5 kWh/t was shown to give an operating work index of 19.6 kWh/t. As shown in the same paper, the grinding ball consumption had been reduced from 1.15 kg/t at start-up to 0.75 kg/t in 1982.

In the case of the Pima comparisons, because there are five lines of smaller mills totalling 15 units for approximately similar tonnage compared to one SAG mill-ball mill line comprising only two units, the shell liner areas exposed to abrasive wear are 3.33 times greater for the conventional plant. If fewer number of larger conventional mills had been available for the comparison within the conventional system, this would have again swung the cost comparison more favor ably towards the conventional system.

Compaction Type Crushing in Roll Crushers

Considerable attention within trade literature and some technical publications is being directed to a so-called new, high intensity crushing, compaction and agglomeration comminution process that was initially applied to European cement operations. The technology being offered has proven beneficial in reducing comminution costs in the cement industry by published amounts of up to 30%, which is of the same order as just shown for mining applications. This technology involves pre-crushing the grinding mill feed in roll crushers.

Many cement clinker grinding mills receive feed sizes ranging from 80% minus 40 mm down to 20 mm, which Bond and Rowland have shown is very inefficient for ball milling and is much coarser than typical mining single-stage ball mills ranging from 80% passing 6 mm to 16 mm. The cement industry clinker mills also make much finer products, approximately 3,000 – 4,000 Blaine (surface area in square centimeters per gram), than flotation feed in mining grinding mills, which is typically 80% minus 120 to 300 µm (microns). Another big difference is that cement clinker is ground dry, which gives additional inefficiencies. As a result, finish grinding on cement clinker typically consumes 30 to 40 kWh/t of product compared to 7 to 15 kWh/t on flotation feed in many mining applications.

It seems puzzling that those recommending compactor crushing imagine they can make a significant reduction on the 8 kWh/t crushing and grinding energy by using a 5 kWh/t inefficient crushing process. The only way this could be achieved is if the crushing rolls in some way weakened the material, thereby lowering its work index. There is some indirect evidence in the literature to indicate lower work index properties following elevated stress levels but little that permits hard analysis of the claims.

Operating Improvements To Conventional Crushing And Grinding Circuits — The Cyprus Sierrita Operation

The Sierrita orebody consists principally of quartz diorite and quartz monzonite porphyry, nominally grading 0.3% Cu and 0.035% Mo. Over the mine life, the strip ping ratio is expected to average 1.5 to 1.0. Conventional truck and shovel mining from 50-foot high benches has been employed at Sierrita, with the notable exception that, whenever possible, primary crushing of both ore and waste has been accomplished close to the active mining zones to allow maximum use of belt conveyors to minimize ore haulage costs.

By 1975, an average daily capacity of 78,040 tonnes (86,000 st) per day had been achieved, and the plant flow sheet was comprised as follows:

- Two 58-89 Allis-Chalmers SUPERIOR primary crushers mounted on top but outside of the pit.

- Four Model 13-84 Allis-Chalmers HYDROCONE secondary crushers.

- Ten Model 5-84 Allis-Chalmers HYDROCONE tertiary crushers.

- Sixteen single stage 16-½’ diameter by 19′ long Allis-Chalmers overflow ball mills fitted with 3,000 HP motors.

Installation of the fixed in-pit ore and waste handling systems was completed in 1977. These facilities in conjunction with continuing crusher development, details published by Woody and Work in 1979, had increased milling throughput to 83,485 tonnes (92,000 st) per day.

Additionally, the joint effort between Sierrita and Boliden Allis (previously Allis-Chalmers) to increase crushing plant productivity was resumed. The large scale study conducted in 1982, just prior to the temporary shutdown, was conducted on highly instrumented production crushers. During testing, large feed and product samples were taken so that breakage energy and ore fracture characteristics could be measured. Specimens from these samples were taken to the Boliden Allis Advanced Technology Center and subjected to high energy pendulum test procedures at various energy levels so that a laboratory work index and the material breakage function could be determined.

The initial efforts to achieve higher power rates (kWh/t) involved the tertiary crushers. Past experience suggested that a hydraulic support pressure greater than 3792 kPa (550 psi) was impractical, and that maintaining choke-fed operation was to be the preferred operating method at Sierrita.

It should be noted by the reader that this phenomenon has been in evidence since the crushers started up in the Sierrita plant. As has been discussed previously in this paper, the power drawn by the crusher relates to the HYDROSET pressure according to 1/sinK1. Because the power is dropping, it means that the resultant crushing force vector angle K1 is moving nearer to the closed side setting.

As speed was increased, the response of the crushing chamber changed such that normal feed entry was inhibited at about 65% of the normal chamber life. Consequently, it was found advantageous to change manganese before it is completely worn out to ensure smooth operation and maximize productivity. It is felt that further chamber development will resolve this problem and allow full manganese utilization.

Step Bearing Components: This is the three-piece thrust washer assembly between the mainshaft and the HYDROSET piston. The bearings have been found in Sierrita to distort under current operating pressures. This does not normally represent a problem as long as matched sets are maintained.

However, it has been noticed that when a machine is shut down, some misalignment might occur, which can result in bearing damage. Careful study showed this damage is most likely to occur during start-up because the oil film is not fully established.

Problems of this type were noted when starting in the speed-up program. During the early phase of the speed-up program, records showed that two tertiary crushers might be damaged during the plant start-up in a weekly operating period. It was noted, however, that, by reducing and then gradually increasing HYDROSET pressure some of the damaged crushers could be returned to full service without additional maintenance. Further examination suggested that the distorted components were shifting relative to one another and thereby affecting the adequacy of the oil film.

Plant Design using high Energy Crusher Technologies

Many crushers do not run continuously drawing the total installed power, as has been demonstrated at Sierrita with worn chambers. As a general observation, ancillary equipment (feeders, conveyors, screens, etc.) in a closed circuit crashing plant making minus 13 mm (½ inch) mill feed typically consumes around 0.75 kWh per ton of plant throughput. The balance for the crushers is very dependent on the work index of the material as well as the mechanical and process efficiencies. For materials of aver-age hardness (work index 14 kWh/tonne, 13 kWh/st), when making minus 13 mm (½ inch) size plant product the fine crusher (secondary and tertiary) energy is seen to range from about 0.75 kWh/t to more than 2 kWh/t based upon the total plant throughput tonnage. If packing occurs due to fixed setting operation and/or higher operating work indices caused by excess fines in crusher feed materials, then the crusher power will be closer to 2 kWh/t. In summary, then, the range of energy consumption from coarse ore stockpiles seems to be between 1.25 and 3.0 kWh/t for many plants making minus 13 mm (½ inch) mill feed.

The crushing process analysis has to be tied in with downstream milling if accurate computations for the total system are to be made. For example, if we increase crushing power in order to save milling energy, the net result of the process interactions have to be made. Most engineering companies when preparing equipment specifications state both the crushing plant output size distribution as well as the grinding mill power requirement without requesting data on the crushing plant power draw so that a good estimation of total comminution performance can be computed.

If autogenous and semi-autogenous processes are to be considered in flow sheet comparisons, there will be problems in estimating grinding mill power consumptions without reasonable scale pilot plant test work. As has already been discussed, the limited availability of media energy of critical sized material and how much of that material will be residing in the mill is the main reason for calculating these mill power levels.

Because of the difficulties in computing autogenous and semi-autogenous mill performance, it has been suggested by Barratt and Allan that for semi-autogenous mills an empirical approach using their proposed efficiency factors might be applied to the Bond laboratory grindability figures to predict SAG mill power requirements. Clearly, such methods are only roughly approximate because in the only sample case study quoted in the paper, for the Escalante project, although the total SAG mill and ball mill combination power was shown to be within 172% of the actual, the method underestimated the SAG mill power by 27.5% and overestimated the ball mill power by 15.2%. Clearly a lot more research work needs to be accomplished if the SAG/ball mill approach is applied with simple laboratory testing so that predictive scale-up calculations are to be made with any accuracy.

Using Efficiency Factors in Comminution Flow Sheets

When comparing crushing and grinding processes, the designer should be aware of the influence of the fundamentally different energy mechanisms.

Crushers. Without exception, should typically process scalped feed with already finish sized product was removed to give maximum size reduction at the lowest possible operating work index. In the crusher computed power draw this is made only that material being engaged in breakage. This means that for a plant assumed to be making minus 13 mm (½ inch) final product, if 25% of that size bypasses the secondary crusher, the laboratory work index would only be applied to the secondary crusher’s performance, which involves only 75% of the total plant feed. .

Grinding Mills: The use of efficiency factors for conventional rod and ball mill performance has been well defined by Rowland. It should be noted that when using laboratory work index numbers, these together with the efficiency factors are applied to the total plant throughput. Therefore, there are no gains to the plant operating work index similar to the type just discussed for crusher performance when scalped material bypasses the machine.

This has been a lengthy discussion because it was necessary to bring together a large amount of research and operational data so the reader can be informed on the comparative efficiency of crushing processes relative to the operation of comminution mechanisms.