Table of Contents

- Screen Vibration Patterns

- Vibrating Screen Design

- Screen Capacity

- Vibrating Screen Capacity

- SCREENING

- Vibrating Screen SPECIFICATIONS

- Floating Circle Motion

- Methods of Fastening Vibrating Screen Cloth

- Double Deck Vibrating Screen—Floor Mounted

- Screen Frame Sizes and Scale-Up Problems

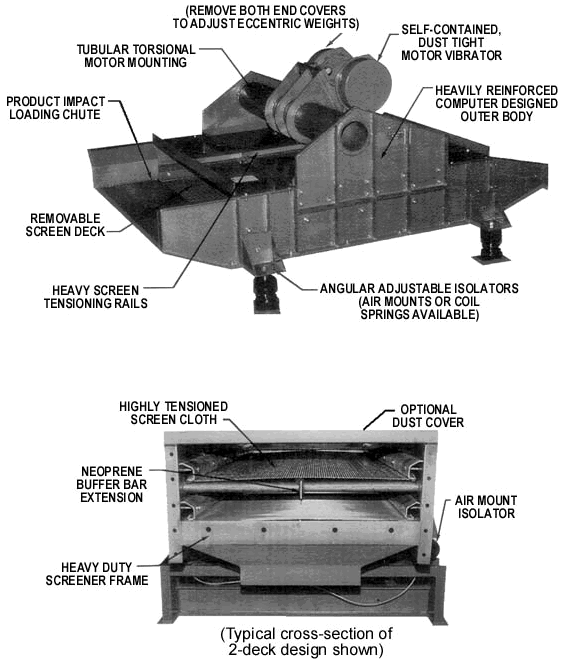

- Major Screen Components

- Fundamentals of Vibrating Screen Size Selection

When the smaller rock has to be classified a vibrating screen will be used. The simplest Vibrating Screen Working Principle can be explained using the single deck screen and put it onto an inclined frame. The frame is mounted on springs. The vibration is generated from an unbalanced flywheel. A very erratic motion is developed when this wheel is rotated. You will find these simple screens in smaller operations and rock quarries where sizing isn’t as critical. As the performance of this type of screen isn’t good enough to meet the requirements of most mining operations two variations of this screen have been developed.

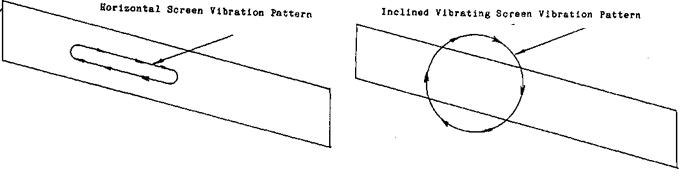

In the majority of cases, the types of screen decks that you will be operating will be either the horizontal screen or the inclined vibrating screen. The names of these screens do not reflect the angle that the screens are on, they reflect the direction of the motion that is creating the vibration.

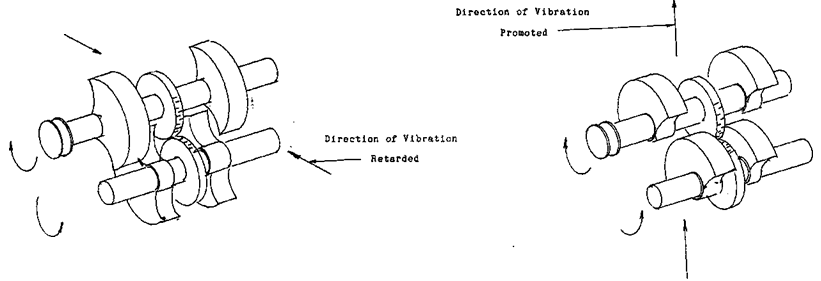

Screen Vibration Patterns

The pattern of vibration for the horizontal screen deck is back and forth while the inclined vibrating screen is circular.

There are different ways to generate the vibration itself. A double counterbalance system is used in the horizontal screen.

The counterbalance weight will alternately promote and retard the direction of vibration depending upon where within each revolution the weights come opposite each other.

An eccentric shaft is used in the inclined vibrating screen. There is an advantage of using this method of vibration generation over the unbalanced flywheel method first mentioned. The vibration of an unbalanced flywheel is very violent. This causes mechanical failure and structural damage to occur. The four-bearing system greatly reduces this problem.

An eccentric shaft is used in the inclined vibrating screen. There is an advantage of using this method of vibration generation over the unbalanced flywheel method first mentioned. The vibration of an unbalanced flywheel is very violent. This causes mechanical failure and structural damage to occur. The four-bearing system greatly reduces this problem. Why these screens are vibrated is to ensure that the ore comes into contact will the screen. By vibrating the screen the rock will be bounced around on top of it. This means, that by the time that the rock has traveled the length of the screen, it will have had the opportunity of hitting the screen mesh at just the right angle to be able to penetrate through it. If the rock is small enough it will be removed from the circuit. The large rock will, of course, be taken to the next stage in the process.

Why these screens are vibrated is to ensure that the ore comes into contact will the screen. By vibrating the screen the rock will be bounced around on top of it. This means, that by the time that the rock has traveled the length of the screen, it will have had the opportunity of hitting the screen mesh at just the right angle to be able to penetrate through it. If the rock is small enough it will be removed from the circuit. The large rock will, of course, be taken to the next stage in the process.

Depending upon the tonnage and the size of the feed, there may be two sets of screens for each machine.

Each set of screens will be called a DECK.

The reason for using two decks is to increase the surface area that the ore has to come into contact with. The top deck will have bigger holes in the grid of the screen. The size of the ore that it will be removed will be larger than that on the bottom. Only the small rock that is able to pass through the bottom screen will be removed from the circuit. In most cases the large rock that was on top of each screen will be mixed back together again.

The main cause of mechanical failure in screen decks is vibration. Even the frame, body, and bearings are affected by this. The larger the screen the bigger the effect. The vibration will crystallize the molecular structure of the metal causing what is known as METAL FATIGUE to develop. The first sign that an operator has indicated that the fatigue in the body of the screen deck is almost at a critical stage in its development are the hairline cracks that will appear around the vibration’s point of origin. The bearings on the bigger screens have to be watched closer than most as they tend to fail suddenly. This is due to the vibration as well.

Vibrating Screen Design

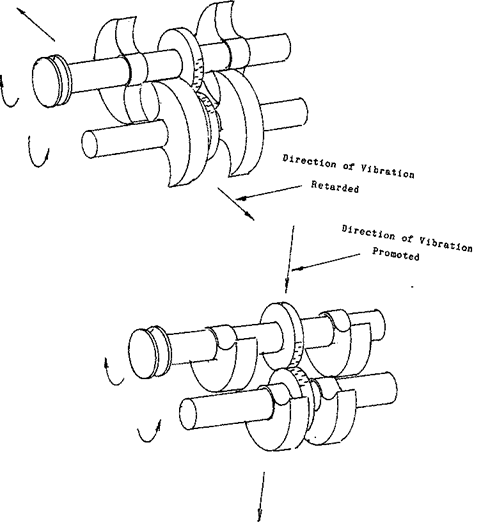

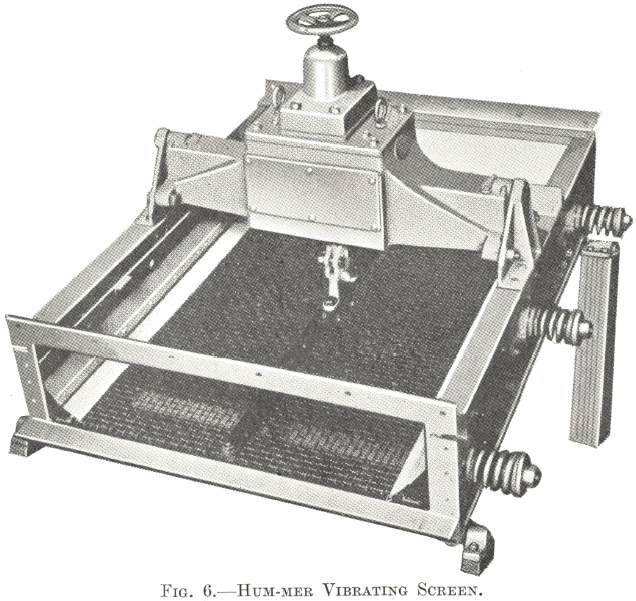

In plant design, it is usual to install a screen ahead of the secondary crusher to bypass any ore which has already been crushed small enough, and so to relieve it of unnecessary work. Very close screening is not required and some sort of moving bar or ring grizzly can well be used, but the modern method is to employ for the purpose a heavy-duty vibrating screen of the Hummer type which has no external moving parts to wear out ; the vibrator is totally enclosed and the only part subjected to wear is the surface of the screen.

The Hummer Screen, illustrated in Fig. 6, is the machine usually employed for the work, being designed for heavy and rough duty. It consists of a fixed frame, set on the slope, across which is tightly stretched a woven-wire screen composed of large diameter wires, or rods, of a special, hard-wearing alloy. A metal strip, bent over to the required angle, is fitted along the length of each side of the screen so that it can be secured to the frame at the correct tension by means of spring-loaded hook bolts. A vibrating mechanism attached to the middle of the screen imparts rapid vibrations of small amplitude to its surface, making the ore, which enters at the top, pass down it in an even mobile stream. The spring-loaded bolts, which can be seen in section in Fig. 7, move with a hinge action, allowing unrestricted movement of the entire screening surface without transmitting the vibrations to the frame.

One, two, or three vibrators, depending on the length of the screen, are mounted across the frame and are connected through their armatures with a steel strip securely fixed down the middle of the screen. The powerful Type 50 Vibrator, used for heavy work, is shown in Fig. 7. The movement of the armature is directly controlled by the solenoid coil, which is connected by an external cable with a supply of 15-cycle single-phase alternating current ; this produces the alternating field in the coil that causes the up-and-down movement of the armature at the rate of thirty vibrations per second. At the end of every return stroke it hits a striking block and imparts to the screen a jerk which throws the larger pieces of ore to the top of the bed and gives the fine particles a better chance of passing through the meshes during the rest of the cycle. The motion can be regulated by spiral springs controlled by a handwheel, thus enabling the intensity of the vibrations to be adjusted within close limits. No lubrication is required either for the vibrating mechanism or for any other part of the screen, and the 15-cycle alternating current is usually supplied by a special motor-generator set placed somewhere where dust cannot reach it.

The Type 70 Screen is usually made 4 ft. wide and from 5 to 10 ft. in length. For the rough work described above it can be relied upon to give a capacity of 4 to 5 tons per square foot when screening to about ½ in. and set at a slope of 25 to 30 degrees to the horizontal. The Type 50 Vibrator requires about 2 h.p. for its operation.

Screen Capacity

The determination of screen capacity is a very complex subject. There is a lot of theory on the subject that has been developed over many years of the manufacture of screens and much study of the results of their use. However, it is still necessary to test the results of a new installation to be reasonably certain of the screen capacity.

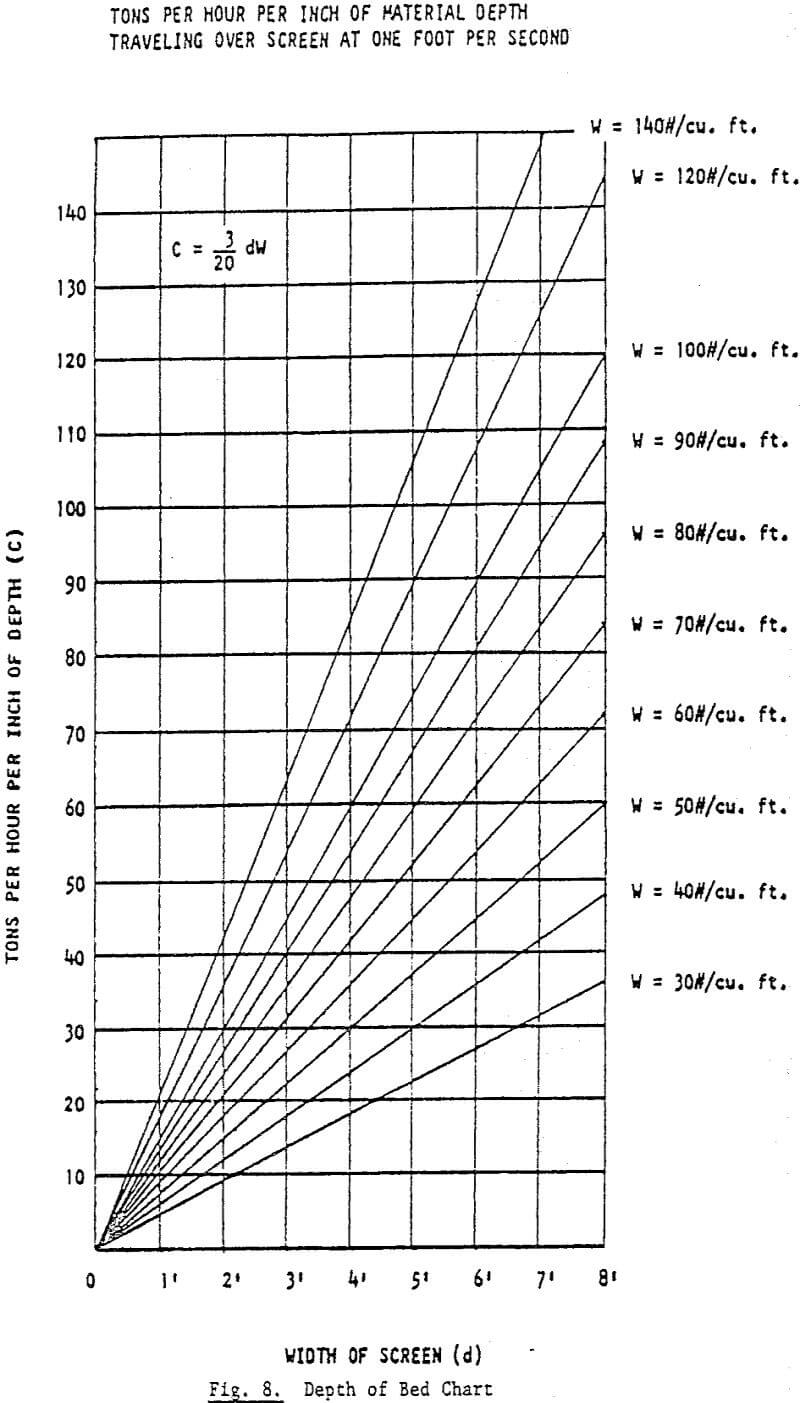

A general rule of thumb for good screening is that: “The bed depth of material at the discharge end of a screen should never be over four times the size opening in the screen surface for material weighing 100 pounds per cubic foot or three times for material weighing 50 pounds per cubic foot. The feed end depth can be greater, particularly if the feed contains a large percentage of fines.” Other interrelated factors are:

- the travel rate or velocity of the material on the screen;

- the vibratory stroke characteristics—amplitude, direction of rotation, type of motion, and frequency; and

- the surface moisture.

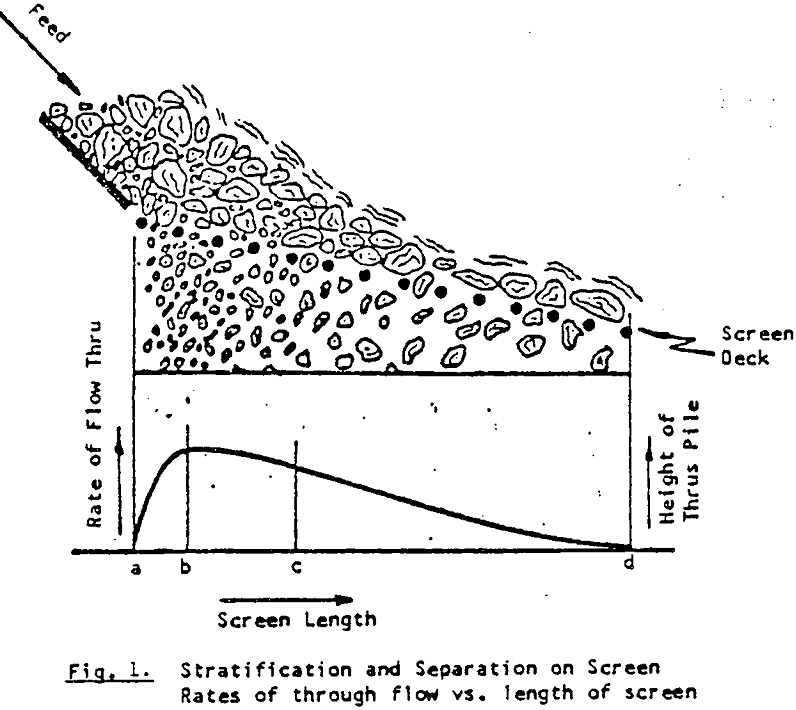

Vibration is produced on inclined screens by circular motion in a plane perpendicular to the screen with one-eighth to ½-in. amplitude at 700-1000 cycles per minute. The vibration lifts the material producing stratification. And with the screen on an incline, the material will cascade down the slope, introducing the probability that the particles will either pass through the screen openings or over their surface.

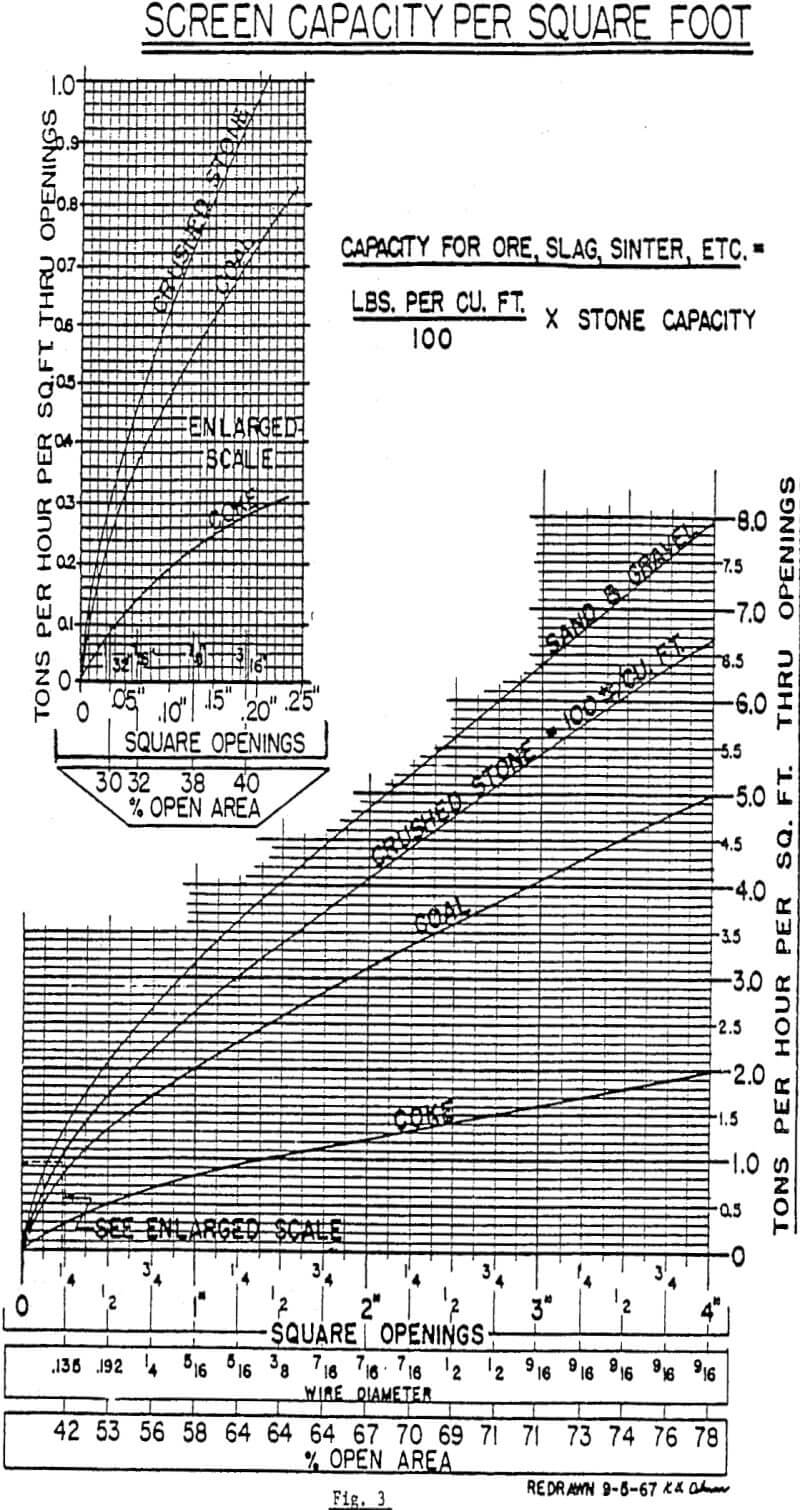

Screen capacity is dependent on the type, available area, and cleanliness of the screen and screenability of the aggregate. Below is a general guide for determining screen capacity. The values may be used for dried aggregate where blinding (plugged screen openings), moisture build-up or other screening problems will not be encountered. In this table it is assumed that approximately 25% of the screen load is retained, for example, if the capacity of a screen is 100 tons/hr (tph) the approximate load on the screen would be 133 tph.

Vibrating Screen Capacity

Screen Size Opening, Number or Inch | TPH per Square Foot | tph for Deck Size Indicated | ||

3 ft x 8 ft | 4 ft x 10 ft | 4 ft x 14 ft | ||

No. 8 | 1.25 | 30 | 50 | 70 |

1/8 | 1.5 | 36 | 60 | 84 |

3/16 | 2 | 48 | 80 | 112 |

| 0.25 | 2.5 | 60 | 100 | 140 |

3/8 | 3.25 | 78 | 130 | 182 |

| 0.5 | 3.75 | 90 | 150 | 210 |

| 5/8 | 4.25 | 102 | 170 | 238 |

0.75 | 4.75 | 114 | 190 | 266 |

| 7/8 | 5.25 | 126 | 210 | 294 |

1 | 5.75 | 138 | 230 | 322 |

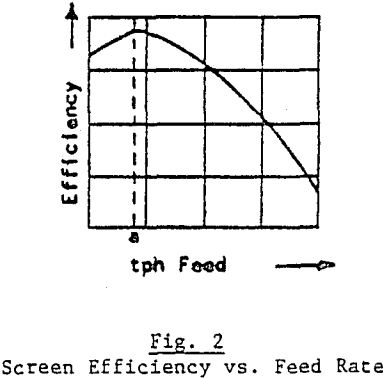

It is possible to not have enough material on a screen for it to be effective. For very small feed rates, the efficiency of a screen increases with increasing tonnage on the screen. The bed of oversize material on top of the marginal particles—stratification —prevents them from bouncing around excessively, increases their number of attempts to get through the screen, and helps push them through. However, beyond an optimum point increasing tonnage on the screen causes a rather rapid decrease in the efficiency of the screen to serve its purpose.

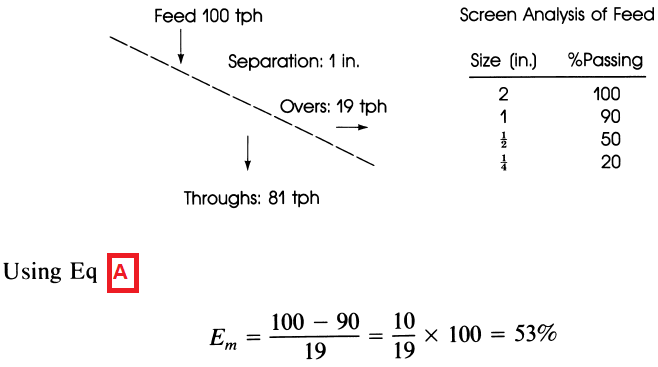

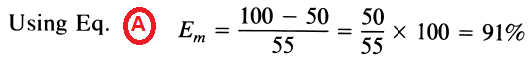

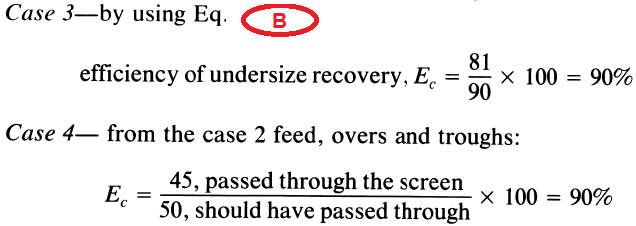

Two common methods for calculating screen efficiency depend on whether the desired product is “overs” or “throughs” from the screen deck. If the oversize is considered to be the product, the screen operation should remove as much as possible of the undersize material. In that case, screen performance is based on the “efficiency of undersize removal.” When the “throughs” are considered to be the product, the operation should recover as much of the undersize material as possible. In that case, screen performance is based on the “efficiency of undersize recovery.”

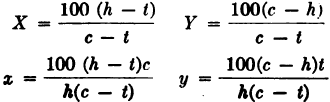

These efficiency determinations necessitate taking a sample of the feed to the screen deck and one of the material that passes over the deck, that is, does not pass through it. These samples are subjected to sieve analysis tests to find the gradation of the materials. The results of these tests lead to the efficiencies. The equations for the screen efficiencies are as follows:

1. Efficiency of undersize removal,

2. Efficiency of undersize recovery,

where: f0 and f1, from analysis of the feed to the screen deck and fp and fs are from analysis of the feed passing over or through the screen.

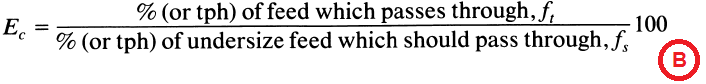

Examples to show how these equations are used will help. They can be illustrated by simple diagrams and arrows for the flow of material in the following cases:

Case 1—where the amount of oversize material is small and so the stratification is poor and the screen efficiency is low.

Case 1—where the oversize material is small:

Case 2—where the amount of oversize material is large promoting better stratification and screen efficiency.

Case 2—where the amount of oversize is relatively high:

In both cases the amount of undersize material, which is included in the material that goes over the screen is relatively small. In Case 1 the “undersize” going over the screen is 19 – 10 = 9 tph, whereas in Case 2 the “undersize” going over is 55 – 50 = 5 tph. That would suggest that the efficiency of the screen in removing undersize material is nearly the same. However, it is the proportion of undersize material that is in the material going over the screen, that is, not passed through the screen, that determines the efficiency of the screen.

In the first cases the product is the oversize material fed to the screen and passed over it. And screen efficiency is based on how well the undersize material is removed from the “overs.” In other cases the undersize material fed to the screen, that is, the “throughs,” is considered the product. And the efficiency is dependent on how much of the undersize material is recovered in the “throughs.” This screen efficiency is determined by the Equation B above. An example using the case 1 situation for the “throughs” as the product gives a new case to consider for screen efficiency.

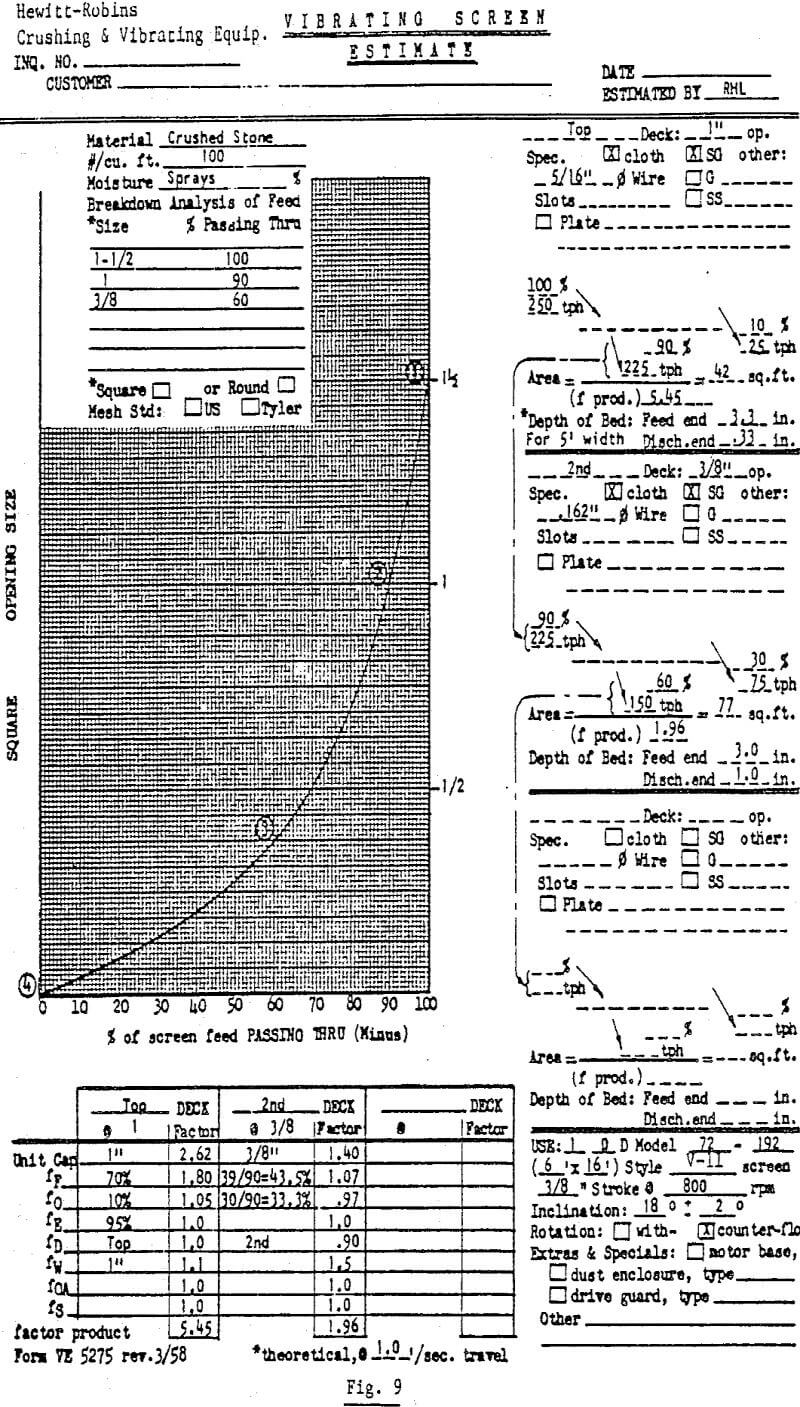

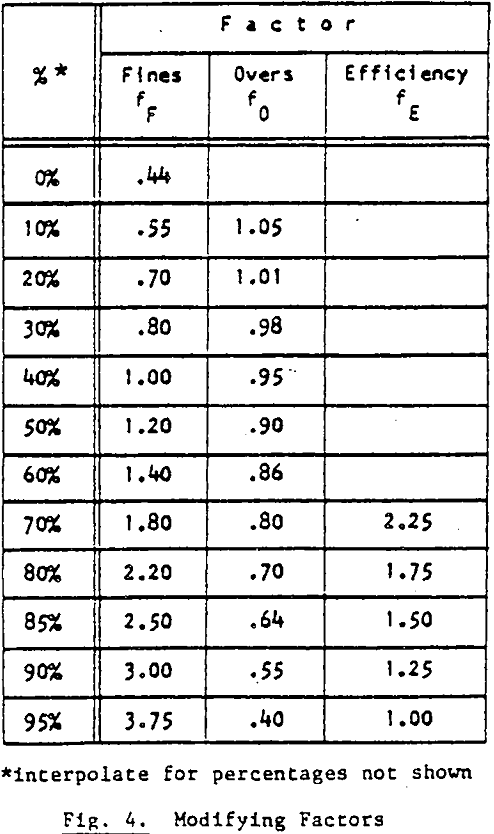

Generally, manufacturers of screening units of one, two, or three decks specify the many dimensions that may be of concern to the user, including the total headroom required for screen angles of 10-25° from the horizontal. Very few manufacturers show in their screen specifications the capacity to expect in tph per square foot of screen area. If they do indicate capacities for different screen openings, the bases are that the feed be granular free-flowing material with a unit weight of 100 lb/cu ft. Also the screen cloth will have 50% or more open area, 25% of total feed passing over the deck, 40% is half size, and screen efficiency is 90%. And all of those stipulations are for a one-deck unit with the deck at an 18° to 20° slope.

The determinants for screen selection are:

- Maximum tons per hour to be screened, that is, the product requirements as specified or otherwise established.

- Material size make-up as found by sieve analysis; product screen analysis from any crusher will vary widely depending upon the material, quarry conditions, and the amount of fines or product size in the initial feed at the time sample was taken—reasons manufacturers do not give screen capacities.

- Type of material and its weight per cubic foot in the crushed or loose state.

- Separation of material desired on each deck.

- Surface moisture carried by the material, if the screening is to done dry, or the amount of water with the feed if the screening is to be done wet.

As was discussed with screen efficiencies, there will be some “overs” on the first passes that will contain undersize material but will not go through the screen. This material will continue recirculating until it passes through the screen. This is called the circulating load. By definition, circulating load equals the total feed to the crusher system with screens minus the new feed to the crusher. It is stated as a percentage of the new feed to the crusher. The equation for circulating load percentage is:

R = 100/E/r-1

where R = circulating load, %

E = screen efficiency, %

r = % oversize in crusher product

To help understand this determination and the equation use, take the example of 200 tph original or new material to the crusher. Assume 100% screen efficiency and 30% oversize in the crusher input. For the successive cycles of the circulating load:

Pass Through | Oversize Material | Tons per hour | |

1 | 200 x 0.30 | = | 60.0 |

2 | 200 x 0.30 x 0.30 | = | 18.0 |

3 | 200 x 0.30 x 0.30 x 0.30 | = | 5.40 |

| 4 | 200 x 0.30 x 0.30 x 0.30 x 0.30 | – | 1.62 |

5 | 200 (0.30)(0.30)(0.30)(0.30)(0.30) | 0.49 | |

85.7 tph | |||

| R = 100/(100/30-1) = 100 /2.33 = 42 9% |

Therefore, circulating load = new feed to crusher times R = 200 X 0.429 = 85.8 tph

The values for the circulating load percentages can be tabulated for various typical screen efficiencies and percents of oversize in the crusher product from one to 99%. This will expedite the determination for the circulating load in a closed Circuit crusher and screening system.

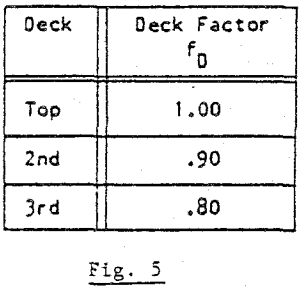

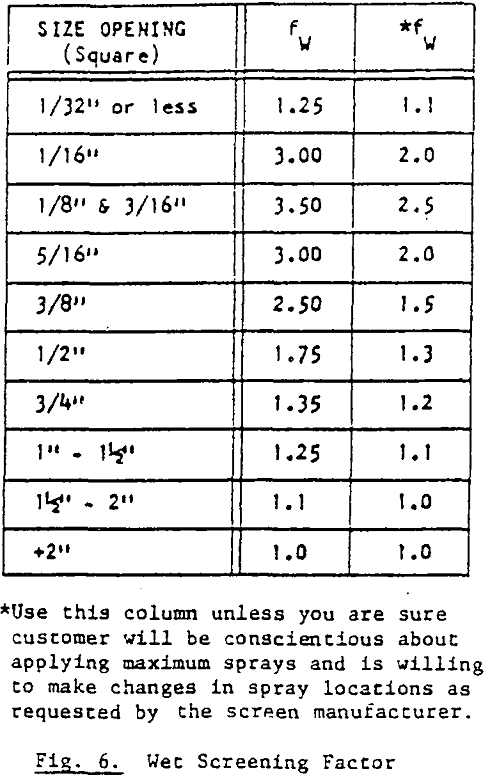

Among the key factors that have to be taken into account in determining the screen area required is the deck correction. A top deck should have a capacity as determined by trial and testing of the product output, but the capacity of each succeeding lower deck will be reduced by 10% because of the lower amount of oversize for stratification on the following decks. For example, the third deck would be 80% as effective as the top deck. Wash water or spray will increase the effectiveness of the screens with openings of less than 1 in. in size. In fact, a deck with water spray on 3/16 in. openings will be more than three times as effective as the same size without the water spray.

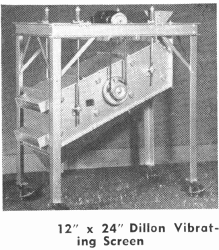

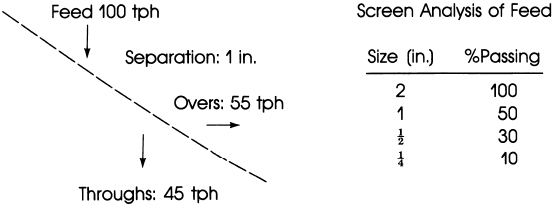

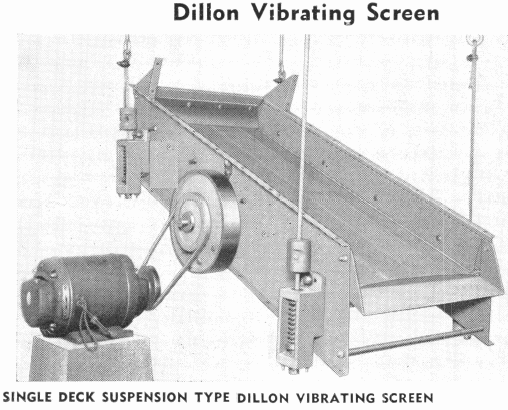

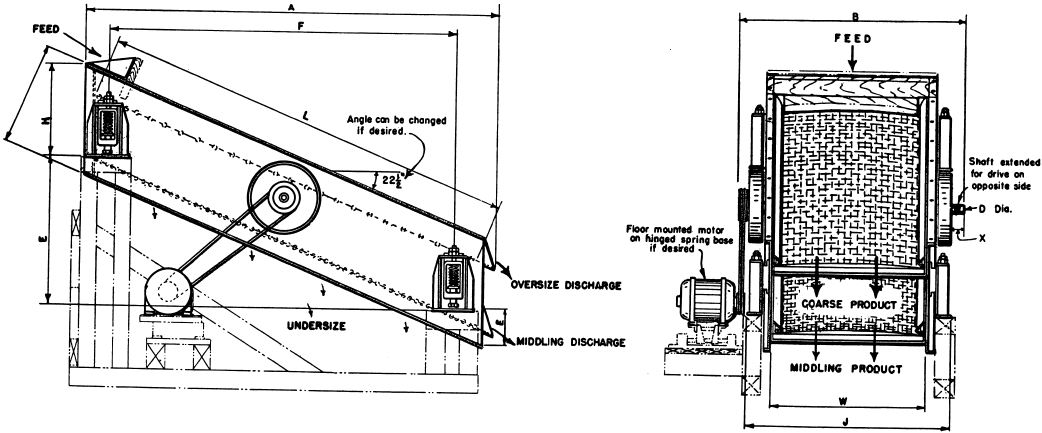

SCREENING

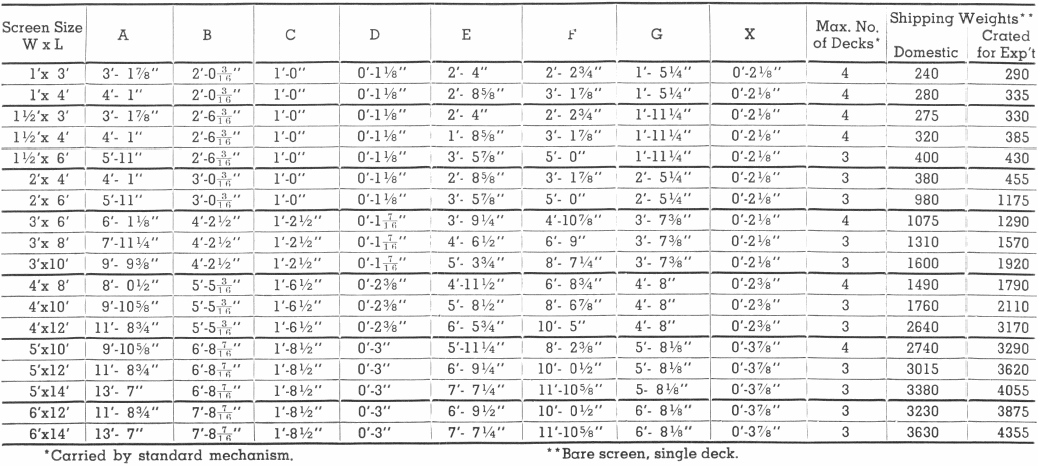

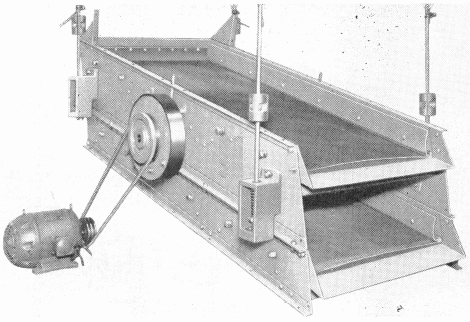

For efficient wet or dry screening—Hi-capacity, 2-bearing design. Flywheel weights counterbalance eccentric shaft giving a “true-circle” motion to screen. Spring suspensions carry the weight. Bearings support only weight of shaft. Screen is free to “float” and follow positive screening motion without power-consuming friction losses. Saves up to 50% HP over 4- bearing types. Sizes 1 x 2′ to 6′ x 14′, single or double deck types, suspended or floor mounted units. Also Revolving (Trommel) Screens. For sizing, desliming or scrubbing. Sizes from 30″ x 60″ to 120″.

The Vibrating Screen has rapidly come to the front as a leader in the sizing and dewatering of mining and industrial products. Its almost unlimited uses vary from the screening for size of crusher products to the accurate sizing of medicinal pellets. The Vibrating Screen is also used for wet sizing by operating the screen on an uphill slope, the lower end being under the surface of the liquid.

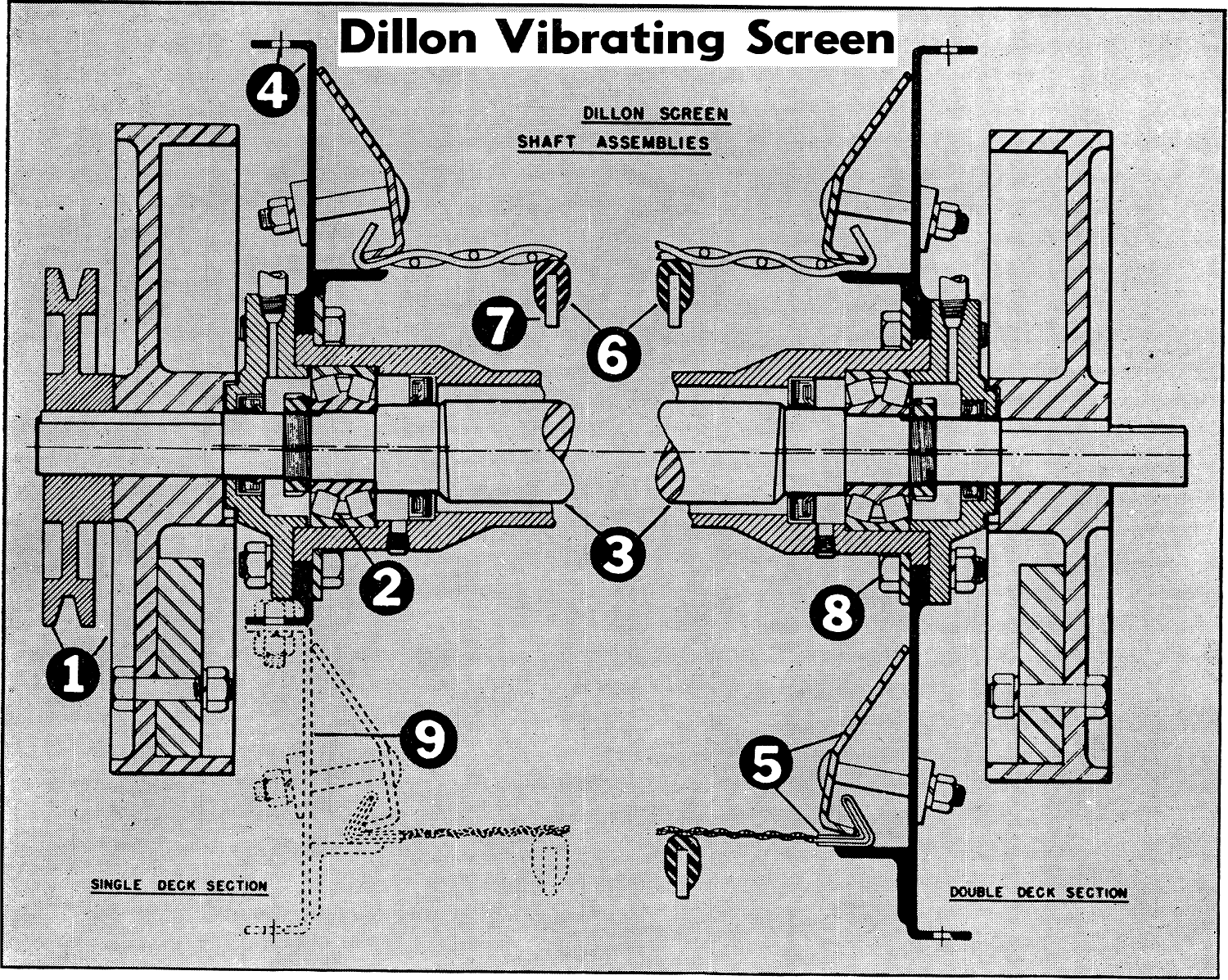

The main feature of the Vibrating Screen is the patented mechanism. In operation, the screen shaft rotates on two eccentrically mounted bearings, and this eccentric motion is transmitted into the screen body, causing a true circular throw motion, the radius of which is equivalent to the radius of eccentricity on the eccentric portion of the shaft. The simplicity of this construction allows the screen to be manufactured with a light weight but sturdy mechanism which is low in initial cost, low in maintenance and power costs, and yet has a high, positive capacity.

The Vibrating Screen is available in single and multiple deck units for floor mounting or suspension. The side panels are equipped with flanges containing precision punched bolt holes so that an additional deck may be added in the future by merely bolting the new deck either on the top or the bottom of the original deck. The advantage of this feature is that added capacity is gained without purchasing a separate mechanism, since the mechanisms originally furnished are designed for this feature. A positive method of maintaining proper screen tension is employed, the method depending on the wire diameter involved. Screen cloths are mounted on rubber covered camber bars, slightly arched for even distribution.

Standard screens are furnished with suspension rod or cable assemblies, or floor mounting brackets. Initial covering of standard steel screen cloth is included for separations down to 20 mesh. Suspension frame, fine mesh wire, and dust enclosure are furnished at a slight additional cost. Motor driven units include totally-enclosed, ball-bearing motors. The Vibrating Screen can be driven from either side. The driven sheave is included on units furnished without the drive.

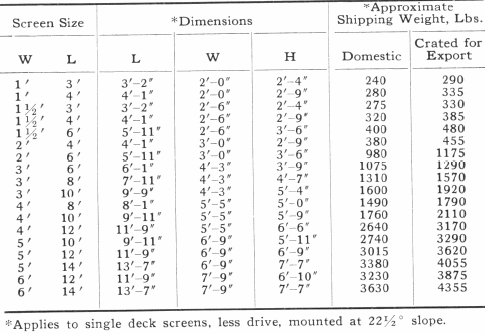

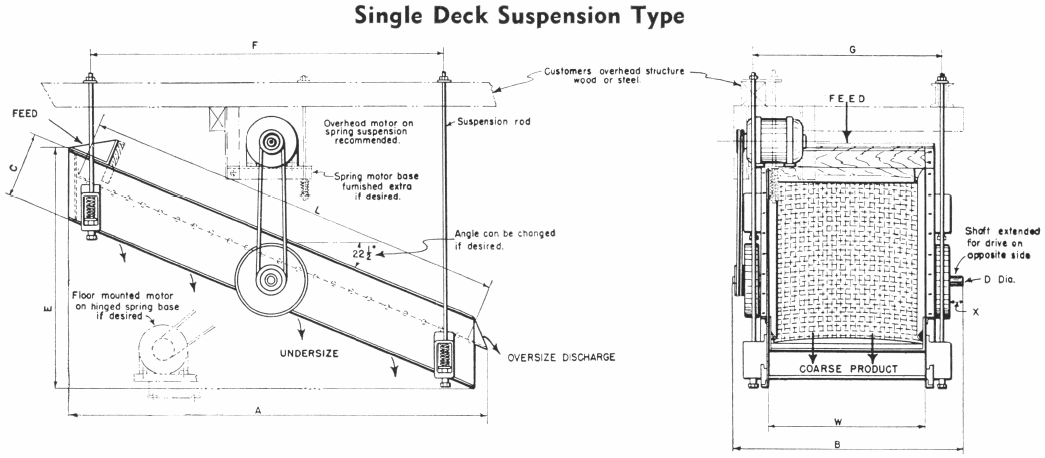

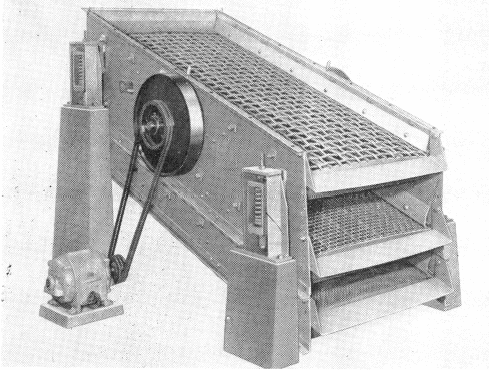

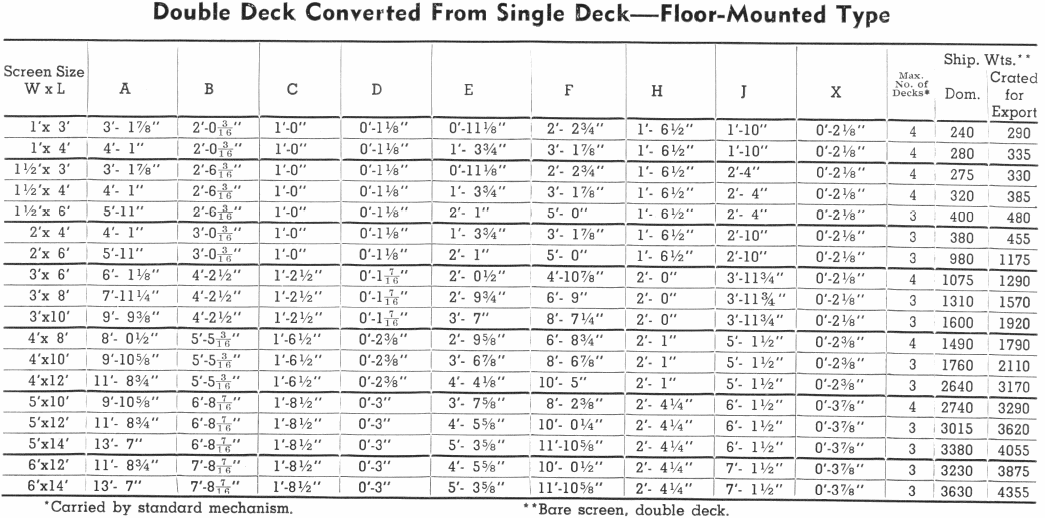

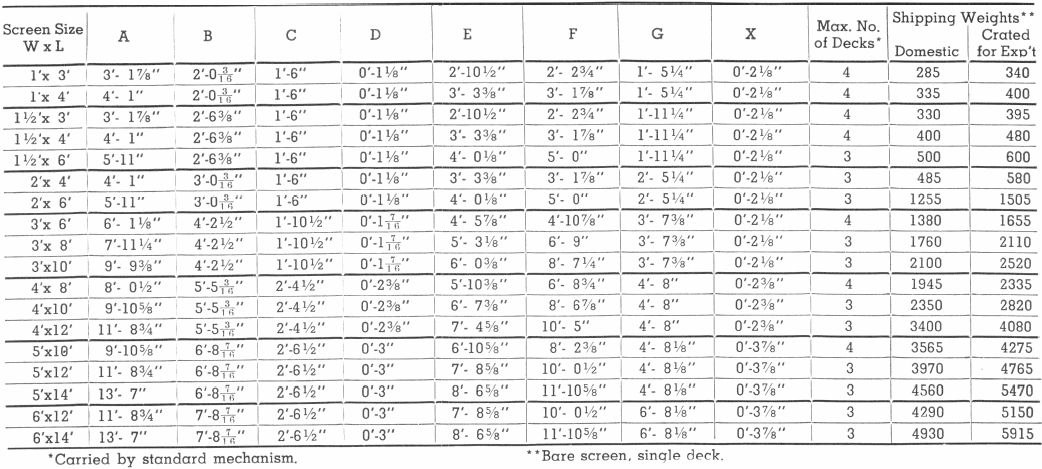

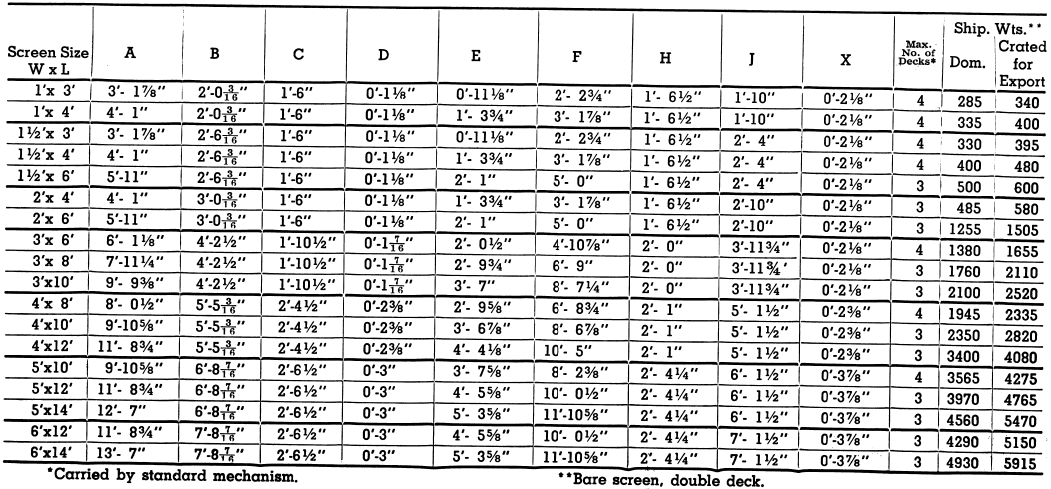

The following table shows the many sizes available. Standard screens listed below are available in single and double deck units. The triple and quadruple deck units consist of double deck units with an additional deck or decks flanged to the original deck. Please consult our experienced staff of screening engineers for additional information and recommendations on your screening problems.

Vibrating Screen Capacity

Vibrating Screen SPECIFICATIONS

- The driven sheave and balance wheels are on the center line of the shaft. The shaft supports no other load and is subjected to no flexing or bending, and rotates freely on its central axis. The driven sheave can be mounted on either end of the shaft depending on whether a right or a left hand drive is desired.

- Only two heavy duty anti-friction bearings are required on the Dillon Screen. Pressure lubrication to center gives complete flushing. Grease seals keep dirt and moisture out of bearings.

- The demountable assembly may be completely removed from either side. The entire screen body gyrates positively and uniformly in a full circle, the radius being equal to the shaft eccentricity.

- The heavy gauge side plates are flanged for additional strength and rigidity. The flanges contain punched bolt holes, accurately lined up for attaching additional screen decks, dust covers, and discharge hoppers.

- Tension readily maintained on quickly replaceable screen sections. The formed angle plates holding the screen securely in position are fastened by standard carriage bolts. The tension mechanism design is dependent on the diameter of the wire in the screen used.

- Rubber-cushioned camber bars arch the screen section and prevent whipping and undue vibration.

- Deep section, full wedged deck panels accurately space and box-brace the side plates.

- Entire assembly securely locked with tightly fitting S.A.E. machine bolts.

- A second and third deck can be conveniently added to a first deck in the field, or a third deck can easily be added to a double deck unit in the field.

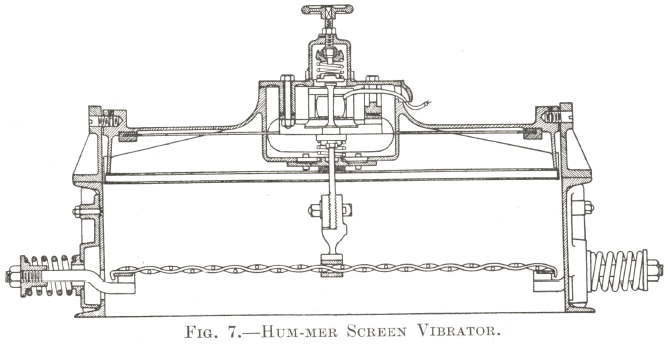

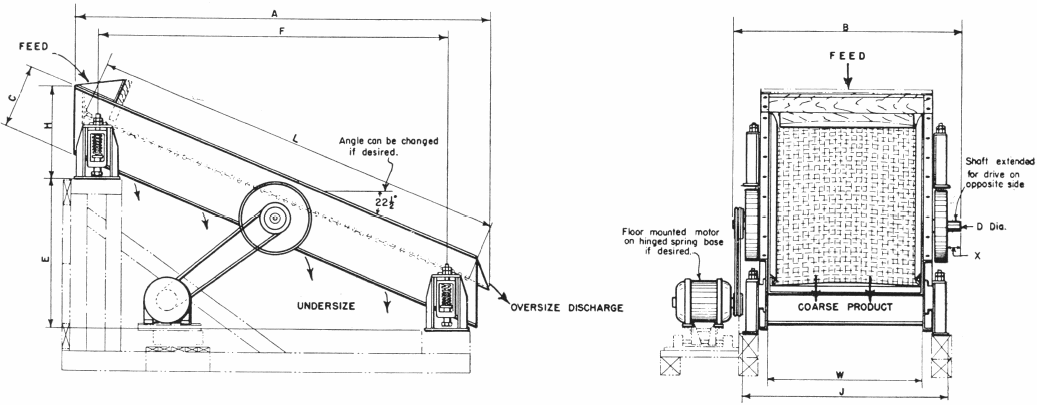

Floating Circle Motion

What It Is

An extremely simple, positive method of imparting uniform “vibration” to the screen body. Using only two bearings and with no dead weight supported by them, the shaft is in effect “floating” on the two heavy-duty bearings.

How It Works

The unit consists of the freely suspended screen body and a shaft assembly carried by the screen body. Near each end of the shaft, an eccentric portion is turned. The shaft is counterbalanced, by weighted fly-wheels, against the weight of the screen and loads that may be superimposed on it. When the shaft rotates, eccentric motion is transmitted from the eccentric portions, through the two bearings, to the screen frame.

The patented design of Dillon Vibrating Screens requires just two bearings instead of the four used in ordinary mechanical screens, resulting in simplicity of construction which cuts power cost in half for any screening job; reduces operating and maintenance costs.

With this simplified, lighter weight construction all power is put to useful work thus, the screen can operate at higher speeds when desired, giving greater screening capacity at lower power cost.

The “sting” of the positive, high speed vibration eliminates blinding of screen openings.

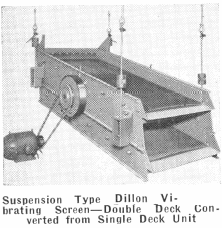

ILLUSTRATION AT LEFT TRIPLE DECK CONVERTED FROM DOUBLE DECK DILLON SCREEN

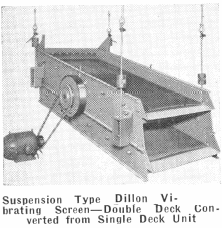

Double Deck Converted From Single Deck—Suspension Type

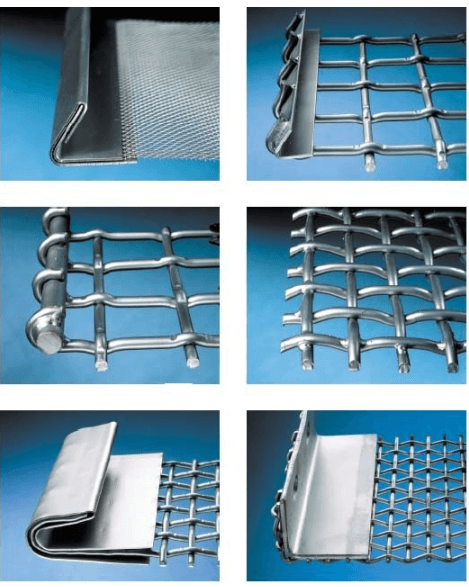

Methods of Fastening Vibrating Screen Cloth

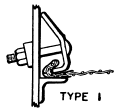

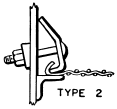

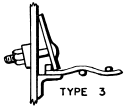

The sketches below demonstrate the four standard methods of fastening a screen cloth to the Dillon Screen. The choice of method is generally dependent on screen wire diameters. It is recommended that the following guide be followed:

Type I: A bent metal reinforcement casing around the bent screen to form a hooked edge. To be used on screen wires having a diameter less than one-eighth inch.

Type II: The wire is bent into a hooked edge and has no metal casing reinforcement. To be used on screen wires having a diameter from one-eighth inch to one-quarter inch.

Type III: A one-half inch square bar is welded to the edge of the screen cloth. For screen wires having a diameter from one-quarter inch to three- eighths inch.

Type IV: For screen wires having a diameter of three-eighths inch and above.

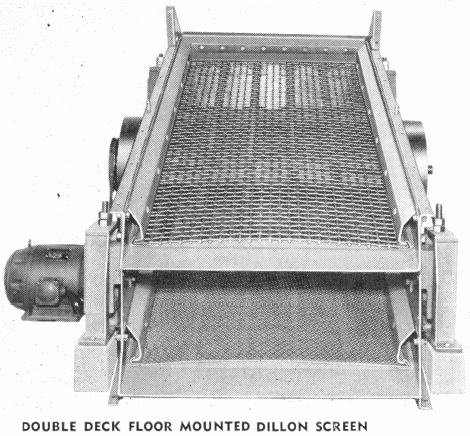

Double Deck Vibrating Screen—Floor Mounted

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.

Screen Frame Sizes and Scale-Up Problems

Major Screen Components

Now, essentially you can break screens down into three major components, namely:

- Live Frame (Sideplates and Crossmembers).

- Vibrator (Heart).

- Mounting Parts (Steel Coil or Rubber Springs).

It would seem appropriate to examine and relate how each of these components has grown over the past 70 years.

- Sideplates: 1/8″ to 3/16″ to ¼” to 5/16″ to 3/8″ to ½” to 5/8″ plus vertical stiffeners .

a. Plus Top Chord Angles up to 6″.

b. Plus Bottom Chort Angles up to 6″. - Vibrators:

a. Single Shaft with 40mm bearings all the way through 240mm bearings.

b. Dual Shafts with 60mm through 200mm bearings.

c. Four-Shaft Horizontal Screens with eight 130mm through 160mm bearings.

d. Six Shaft Horizontal Screens with twelve 130mm bearings per vibrator vibrating 82,000 pounds.

e. Inclined Screens with four shafts and eight 140mm bearings.

f. Probably there are other combinations that haven’t come to my attention.

Fundamentals of Vibrating Screen Size Selection

Before Separation can take place we need to get the fine particles to the bottom of the pile next to the screen deck openings and the coarse particles to the top. Without this phenomenon, we would have all the big particles blocking the openings with the fines resting atop of them and never going through.

Once we have Stratification the small pieces are accepted and pass through while the coarse are rejected and pass over the screen deck.

We need to state that 100% efficiency, that is, putting every undersize particle through and every oversize particle over, is impossible. If you put 95% of the undersize pieces through we in the screen business call that commercially perfect.

- Formula for efficiency:

a. Simply stated the formula is:

Percent of feed that actually passes/Percent of the feed which is actually undersize and should pass through

b. Contamination of Overs product results if you have poor efficiency of undersize removal.

c. You can also have contamination of through product if openings are oversize.

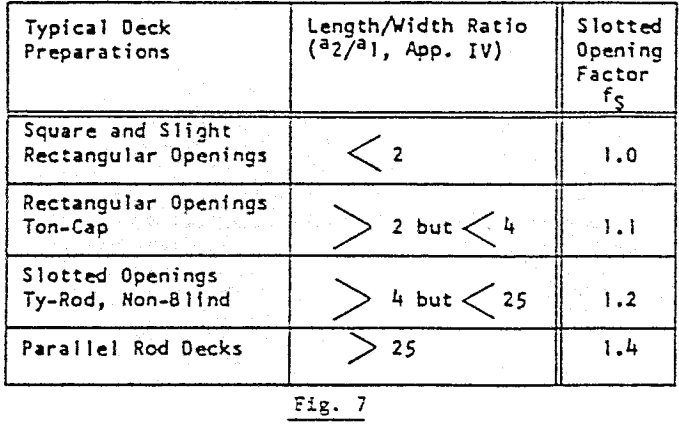

Depth of Bed Considerations must be given to each deck