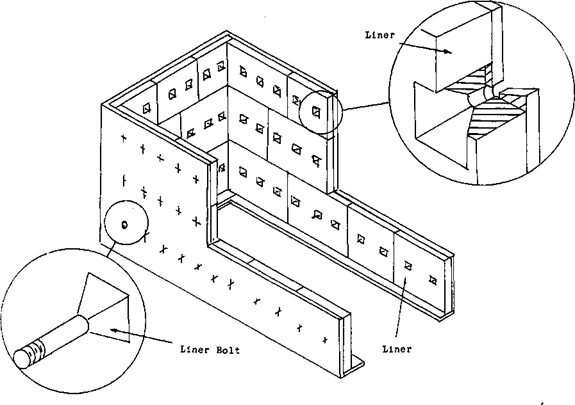

These liners have a high carbon content to give them the hardness required. This carbon makes welding these liners very difficult. For this reason the liners are bolted in place. As I mentioned earlier these bolts make excellent early warning indicators for worn-out liners.

When the wear on the liner becomes great enough to wear the head of the bolt off, the bolt will fall out. The operator when making his rounds should notice things like this, investigate, and report it to his supervisor so the liners may be replaced.

When the wear on the liner becomes great enough to wear the head of the bolt off, the bolt will fall out. The operator when making his rounds should notice things like this, investigate, and report it to his supervisor so the liners may be replaced.

Having more than one bolt at a time missing could mean that a liner has fallen out. If this happens the missing liner should be reported immediately. A stray liner loose in the circuit may cause belt damage or plugged chutes.

There is one more area of concern for the operator when dealing with chutes. There is a dust seal that makes contact between the chute and the moving surface of the conveyor. It is called the chute SKIRTING.