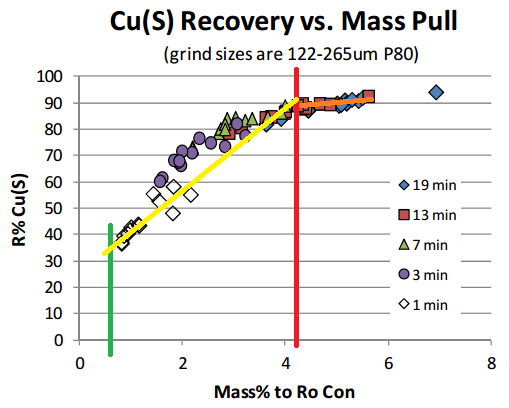

What is flotation mass pull and why does it matter so much? If we consider the total Plant Feed of 2800 TPD as 100% of the mass and we produce say 59% Cu Recovery or 84 TPD of Cu conc, we would find that 3% of the “mass” is in the concentrate. We therefore label %Mass Pull as the % of the material (mass) sent to flotation a “pulled/floated” into the concentrate. This number needs to be as small as possible to consider the flotation to be selective.

Applying the Lab to the Plant:

Obviously if 100% of the feed is sent to conc, a 100% recovery is achieved (without concentration). The idea of selective flotation is to “concentrate” and put as much metal in as little a concentrate mass as possible. Pulling more mass has complicated process and mechanical implications as larger mass often cannot be handled by pumps or flotation cells for lack of volumes.

For base metals plants/concentrators, a stage process that yields more than 20% mass pull, is likely to fails. It does not concentrate enough. Optimum results are obtained at 10% to 15% mass pull.

Any stage of selective flotation, such as a rougher, must significantly upgrade metal. For example, if a rougher circuit is feed 1% Cu, the concentrate produced by that rougher stage and its reagents needs to be an order of magnitude superior to 2X its feed grade. In this case (1% Cu) a rougher conc greater to 2% Cu should be produced. Producing less than 2X upgrade would mean the system is much too inefficient.

The proper/ideal flotation reagent needs to be selective and aims at putting the correct metals in the correct concentrates and maximize specific revenues.

More mass can kill you!

Why is %Mass Recovery/Pull important