The next way that density effects the circuit is in the dispersal quality of the air and reagents. If the density is heavy, the chemicals may not be mixed thoroughly throughout the ore due to the poorer agitation. This may cause mineral losses due to the mineral not being able to come into contact with all of the chemicals or air.

The next way that density effects the circuit is in the dispersal quality of the air and reagents. If the density is heavy, the chemicals may not be mixed thoroughly throughout the ore due to the poorer agitation. This may cause mineral losses due to the mineral not being able to come into contact with all of the chemicals or air.

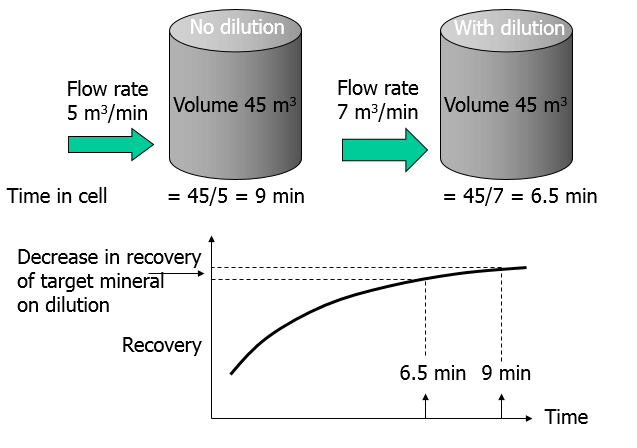

If on the other hand the density is too light, the time that the reagents have to react on the minerals is lessened. This time is termed CONDITIONING TIME not to be confused with Flotation RETENTION TIME.

Retention time is the time that the ore spends within a process or circuit. Conditioning time is the time that the reagents have to become attached or dispersed through the ore before the reagent is required to perform the function it was designed to do. The extra water that the light density represents effects the retention time as well. A lower retention time means there will be less of an opportunity for the air bubbles to come into contact with the mineral to carry it away.

The method of determining the density is the same method that is used on a grinding circuit. That is to weight the slurry of either the heads or the tails.