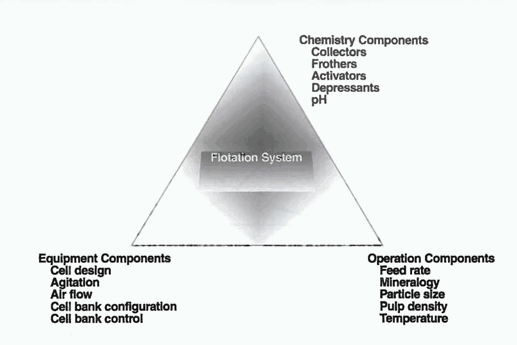

Successful industrial practice has shown that froth flotation sytem needs to be viewed both at the plant level and at the research level as a highly interactive system consisting of equipment, chemistry, and operational factors. A long history of plant tests has shown rather clearly that it is not very fruitful to work in any one of the factors without having some awareness of how the others interact. Sometimes factors are self-compensating, and at other times they reinforce some activity in rather complicated ways. It is not only the main effects that are important in flotation but also the first-order and even the second-order interactions that can dominate. What are the true limitations of the froth flotation system and when are the various control variables manipulated in an optimal fashion?

- Evaluating Copper Rougher-Scavenger Flotation Circuit Performance

- Mineral Composition and Fragmentation

- Flotation Process Development and Assessment

- Measure and Evaluate Flotation Scavenger Tail Losses