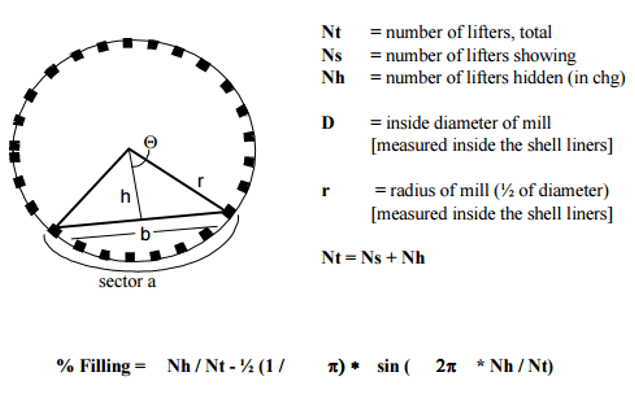

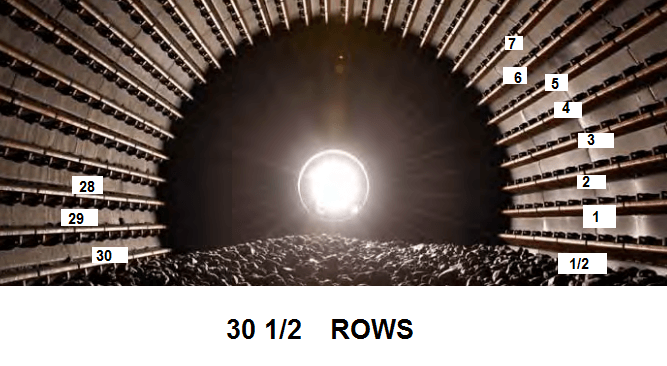

This is a 2nd Method for estimation or measuring the steel charge volume inside a mill. If dealing with a full SAG/AG mill, this will give you the rock load%. If you can count liners, you’ll have your answer.

The 1st method uses similar parameters.

Find more at https://sagmilling.com/tools_millfilling

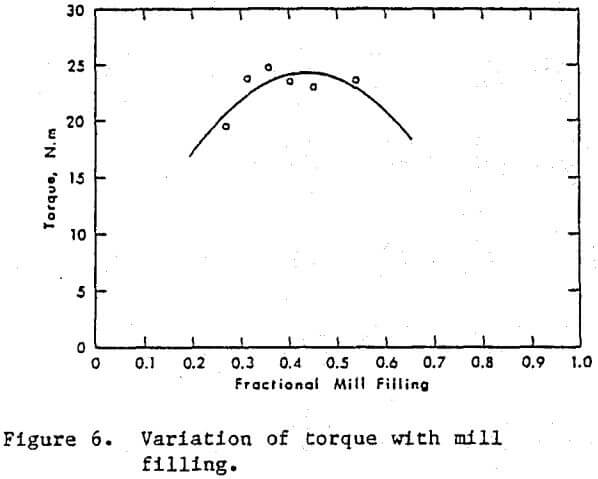

Effect of Mill Filling on the Energy Input

The effect of mill filling on the energy input is studied by varying the number of discs. Figure 6 shows the variation of torque with mill filling. Mill filling is calculated based on the fraction of the total area occupied by the discs. As expected, the energy input reaches a maximum and then falls off. This simulation was done with 2-cm diameter discs, and the mill speed was kept at 62% of the critical speed.