Here is a method on how to conduct a cyanidation bottle roll test AKA Cyanide Gold Extraction Process:

- Riffle out 400 grams of the ore.

- Grind to pass 200 microns (“13-15 minutes for hard rock ores;” 10 minutes for oxidized ore) grind at 35% solids.

- Wet screen. Retain and dry fractions. Settling overnight of – 45um will be required. Decant and dry. Perform cyclosiing on – 45um fraction. Ensure to include – 45um material dry screened from remaining size fractions. (20 minutes on Ro-tap screen shaker).

- Reconstitute sample – add to bottle along with same weight of 0.1% (1 gram/litre) NaCN solution, to give 50% solids. Adjust pH to 10.0 – 10.5, with measured lime additions.

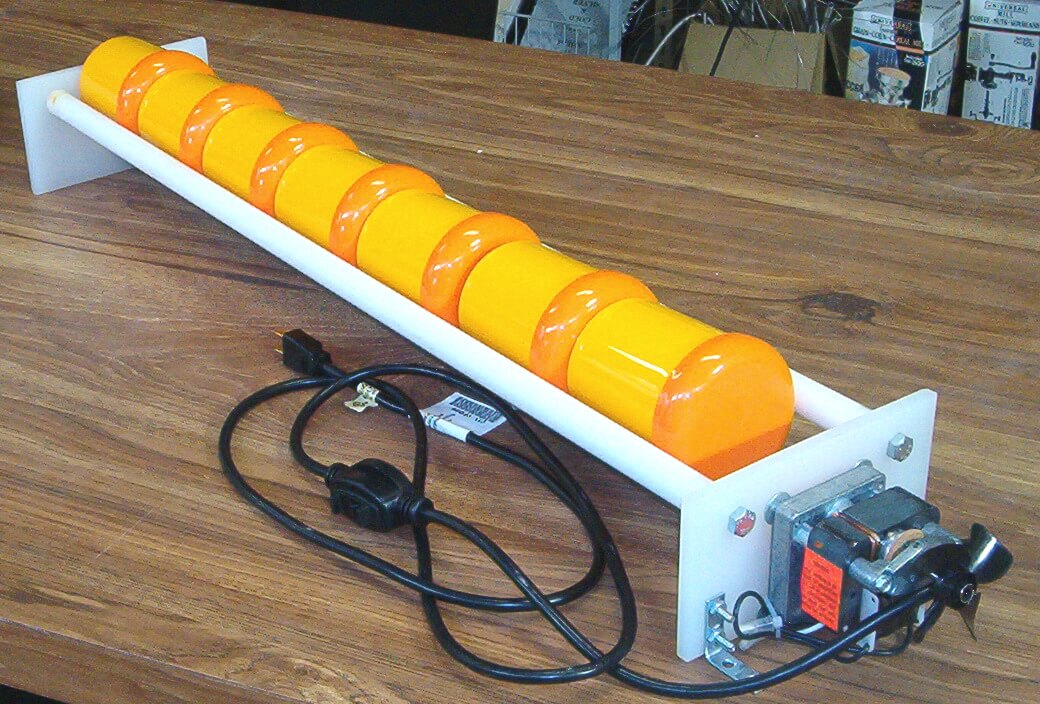

- Put bottle on rolls (with variable speed setting set at zero – this is sufficient agitation) – if using two bottles, place caps away from each other, and start timing.

- Connect up air lines such that air is bubbled through solution.

- When a sample of the pregnant cyanide solution is required, decant 100 mls of pulp, into a beaker. Return to the bottle any previous filtrate, along with 50 ml of cyanide solution (0.1%). Return bottle to rolls.

- Filter pregnant solution from pulp, retaining and labeling the solution. 40-50 mls of pregnant solution is required.

- When final sample (72 hours usually) has been taken, the residual cyanide must be determined. Procedure for this determination is outlined elsewhere.

- Wash solids with warm water and dry, setting aside for final residue.

Comments on this Cyanide Gold Extraction Process/Method:

Instead of cyanidation by bottle leaching on rolls, it may also be more convenient to bottle leach using magnetic stirrers with necessary air bubbled using flexible air lines. Alternatively, a flotation cell could be utilized.