The first one to look at is a simple two belt conveyor system, the ore will come from a draw point. This could be a fine ore bin or a coarse ore stock pile. It is transported by the first conveyor to a transfer chute where it will be transferred to the second belt. The transfer chute has no moving parts but is very important to the operator so let’s stop and look at it.

The design of this chute is very important. If the conveying system is to operate correctly the ore must he put onto the very centre of each belt. If it doesn’t land properly the belt will begin to wander and spillage will have to be cleaned up.

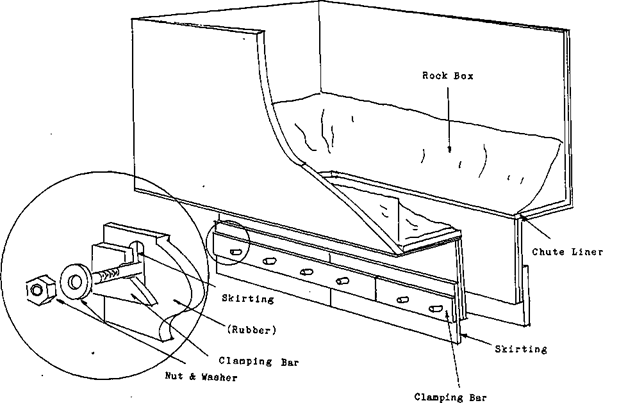

When you look into a chute you will notice a lip that runs around the bottom of the chute. This lip is called the ROCK BOX. What it is for is this, primarily it directs the flow of ore to the centre of the next belt. It also provides a ledge where rock and dust will collect. This prevents the flow of ore from wearing out the bottom of the chute thus changing the ore loading pattern. The abrasion caused by the moving ore will be harmlessly absorbed by the rock on top of the ledge.

When you look into a chute you will notice a lip that runs around the bottom of the chute. This lip is called the ROCK BOX. What it is for is this, primarily it directs the flow of ore to the centre of the next belt. It also provides a ledge where rock and dust will collect. This prevents the flow of ore from wearing out the bottom of the chute thus changing the ore loading pattern. The abrasion caused by the moving ore will be harmlessly absorbed by the rock on top of the ledge.

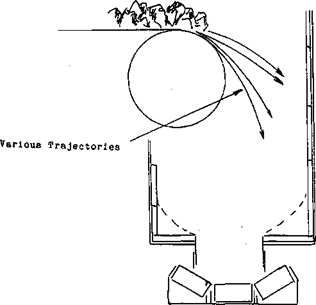

Unfortunately the ore will often hit the side of the chute before it slides across the rock box. This is because the varying volume and size of the rock, plus different speeds that the feeder belt may be travelling at, will cause the TRAJECTORY of the ore to change. This means that the ore will hit the chute at different places.

To protect the chute from wear caused by this ore abrasion, replicable LINERS made from armour plating are fastened to the inside of the chute.