The second group of crusher components consists of the Cone Crusher’s oil system, the Cone Crusher’s dust seal and the thrust-bearing. The oil system, like the one used with the primary crusher, is one that requires a large EXTERNAL RESERVOIR. It has the same features that was described earlier in the chapter that dealt with the Primary crusher. It too lubricates a thrust bearing, Eccentric inner and outer bearing, and crown and pinion gear.

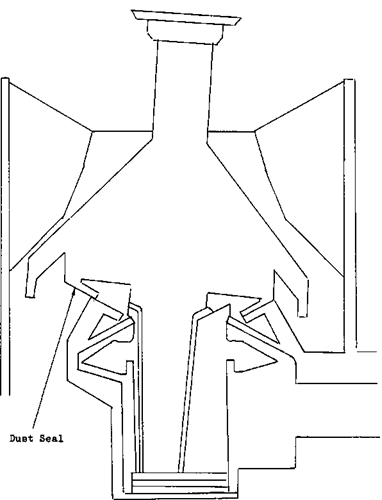

One of the difference in this type of crusher over the gyratory crusher is that these crushers require a DUST SEAL to prevent dust and -dirt from getting into the internal workings of the crusher. The seal is made up of three components. Two rings that circle the crusher. These rings may be made from a variety of materials depending upon the age and type of crusher. Their purpose is to provide a smooth interface that the moving crusher mantle will slide over as it gyrates. The third component is WATER, it is this water that forms the fluid barrier that the dust will not be able to penetrate. Any dirt that comes into contact with the water will be carried away. This makes the water flow a very important item in an operators check list.

Another area that an operator should he checking periodically is under the crusher in the discharge chamber. Under the crusher there is an armour protected arm. This arm provides access for the drive shaft, dust seal water and oil lines. It also provides a place for wire, plastic, and assorted garbage to collect. It should be cleaned off once in a while. Cleaning off this arm also provides the operator with the opportunity of visually checking the liners for wet spots that would indicate water leaking from a worn dust seal.